© 2020

CONTRIVE • B14

33|FIRO.EN

1020

8

www.contrive.it

GAS BURNER

The burner is turned ON/OFF together with device power supply.

A flame simulation test is carried out during pre-purge (waiting time).

The fuel valve

[V]

will be activated only if the ignition output is detected during pre-ignition time.

The fuel valve remains open during the programmed safety time, if a valid flame signal is detected within the safety

time, the valve is kept open: the burner is ON. If no flame is detected the system will lockout.

In accordance with EN746

-

2 and EN676, up to 4 ignition attempts are allowed if the safety is not impaired.

Push the front panel button to reset from lockout (will take place at release).

Flame quenching during burner operation will force the system to lockout, recycle or ignition restoration.

To put the burner out of service (manual shutdown) push the front panel button during the operating cycle.

A post-combustion time (max 20 seconds) is allowed after a lockout or shutdown request, followed by post-purge.

It is possible to share a single rod for ignition and flame detection using special ignition transformers.

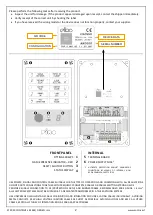

THERMOSTAT

GAS VALVE

K

POWER RELAY

SINGLE ROD CIRCUIT

M

BLOWER

DUAL ROD CIRCUIT

LOW AIR PRESSURE SWITCH

BURNER LOCKOUT

RESET INPUT

ALL SAF

ETY SWITCHES SHOULD BE APPROVED AS LIMIT CONTROLS

THE USE OF ELECTRONIC SWITCHES MAY CAUSE ERRATIC OPERATIONS