© 2020

CONTRIVE • B1444

|FIRO.EN

10

20

6

www.contrive.it

504 – FLAME FAILURE

EN298 §

7.101.2.3

Determines the behavior at flame loss during normal burner operation.

For burners with occasionally unstable flame signal a single recycle (including pre-

purge) or direct ignition restoration can be attempted. The setting is to be

determined on the basis of burner capacity and relevant application standard.

505 – FLAME FAILURE RESPONSE TIME

EN298 §

3.1

05.

1

-

§ 7.101.3.4.3

-

§ 7.101.3.7

If the flame fails during operation, gas valves are switched off within this safety

time that must be in accordance with relevant application standards (default for

EN 298 is 1” and must not exceed 5”

, including valves closing time fo

r EN 746

-2).

509 – ALLOWED POST-COMBUSTION TIME

Flame signal allowed for 20” once fuel valves has been closed.

Lockout occurs when the flame is detected after this post-combustion time.

Useful when fuel valves are distant from the burner.

602 – POSTPURGE TIME

EN298 §

3.124

.

6

Set post-

purge time in forced draught burners according to standards (EN 676).

The flame simulation test is carried out during this time.

This is a merely waiting time if there is no air control.

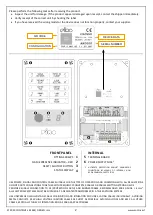

CONFIGURATION CODE

FR

P = P

LA

ST

IC

|

F

RA

=

A

LU

M

IN

UM

ST

AR

T-

UP

MO

DE

.

101

PR

EP

UR

GE T

IM

E .

3

03

SA

FE

TY TI

M

E .

4

02

ST

AR

T-

UP

A

TT

EM

PTS

.

40

3

FL

AM

E

FA

ILU

RE

B

EH

AVIO

R

. 5

04

FL

AM

E F

AI

LU

RE

R

ES

PON

SE

TI

M

E .

5

05

POS

TP

UR

GE

TI

M

E

. 6

02

FRP A

001

03

1

L

01

001