© 2020

CONTRIVE • B1444

|FIRO.EN

10

20

5

www.contrive.it

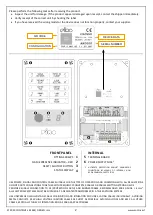

PARAMETERS

101

START-UP MODE

AUTOSTART

A

STANDBY

S

303 PREPURGE (WAITING) TIME

0” …

000

DEFAULT

1

”

… 250”

250

401

PRE-IGNITION TIME

1

0,5”

402

SAFETY TIME

2” …

02

DEFAULT 3”

… 25”

25

403

BURNER STARTUP ATTEMPTS

1

1

2

2

3

3

4

4

504

FLAME FAILURE

LOCKOUT

L

RECYCLE

C

IGNITION RESTORATION

K

505 FLAME FAILURE RESPONSE TIME

1” …

01

DEFAULT

1

”

… 12”

12

602

POSTPURGE (WAITING) TIME

0” …

000

DEFAULT

1

”

… 250”

250

ENCLOSURE

PLASTIC

FRP

ALUMINIUM

FRA

1

NON-

CONFIGURABLE PARAMETER

101 – START-UP MODE

At power-on, once the self-test has been successfully completed, the unit waits in

STANDBY mode until a reset operation is performed from push button

, input or

through a fieldbus remote command. Setting AUTOSTART mode, the cycle starts

automatically, unless the units has been turned off while in lockout.

303 – PREPURGE TIME

EN298 §

3.124

.

1

-

§ 3.124.2

-

§ 3.124.3

-

§ 3.124.4

Set pre-purge time in forced draught burners according to applicable and relevant

standards (EN 676). During this time the flame

simulation test is carried out.

This is a merely waiting time if there is no air control.

401 – PRE-IGNITION TIME

EN298 §

3.135.3

The ignition transformer is turned on 500 ms before the pilot fuel valve to check

the correct operation before supplying the fuel.

This is a fixed time and can not be changed.

402 – SAFETY TIME

EN298 §

3.116

Set the correct time following EN 746

-2 (or other relevant) requirements:

Natural draught burners

≤

35

0 kW → 10”

> 35

0 kW → 5”

IGNITION POWER

≤

33% NOMINAL POWER WITH MAXIMUM OF 350 KW

Forced draught burners

≤

7

0 kW → 5”

> 70kW

→

3”

IGNITION POWER ≤ 10%

NOMINAL POWER WITH MAXIMUM OF 350 KW

403 – BURNER STARTUP ATTEMPTS

EN

746

-2 -

EN676

When the flame is not detected at the end of startup safety time, it is possible to

make up to 4 startup attempts (including the first one), if the safety of the

application is not impaired, repeating the cycle from the beginning.

A lockout will occur if no flame has formed within programmed attempts.