© 2020

CONTRIVE • B1444

|FIRO.EN

10

20

2

www.contrive.it

Please perform the following tasks after receiving the product:

•

Inspect the unit for damage. If the product appears damaged upon receipt, contact the shipper immediately.

•

Verify receipt of the correct unit by checking the label.

•

If you have received the wrong model or the device does not function properly, contact your supplier.

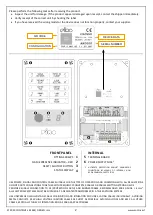

FRONT PANEL

INTERNAL

FITTING SCREWS

1

5

TERMINAL BOARD

FLAME PRESENCE INDICATOR – RED

2

6

POWER SUPPLY FUSE

1

RESET / SHUTOFF BUTTON

3

1

ULTIMATE PROTECTION AGAINST DANGEROUS

CONDITIONS BY MEANS OF

INTERNAL, NON

REPLACEABLE

5A SAFETY FUSE

STATUS DISPLAY

4

USE POWER, SIGNAL AN

D CONTROL CABLE SUITABLE FOR THE TYPE OF

OPERATION AND COMPLYING WITH ALL REGULATIONS

DO NOT ROUTE CONNECTIONS TOGETHER WITH FREQUENCY CONVERTER

CABLES OR CABLES EMI

TTING STRONG FIELDS

PROVIDE

RELIABLE CONNECTION

TO PE (PROTECTION EA

RTH) AND BURNER FRAM

E, RECOMMENDED WIRE GAUGE >

4

mm

2

ALL ELECTRONIC SYSTE

MS MUST BE SUPPLIED BY A DEDICATED TRANS

FORMER IN A TN-S EARTHING SYSTEM

USE UNSCREENED HIGH-

VOLTAGE CABLE FOR IG

NITION AND IONIZATION ROD LI

NES, LAYING CABLES I

NDIVIDUALLY, AVOIDING

METAL CONDUITS. KEEP HIGH VOLTAGE IG

NITION CABLES AS SHORT AS POSSIBLE, AVOI

DING LOOPS AND KEEP ALL OTHER

CABLES, ESPECIALLY T

HOSE OF IONIZATION ROD, AS FAR APART

AS POSSIBLE

DEVICE DATA

QR CODE

SERIAL NUMBER

CONFIGURATION