CONTRACOR

®

CAB-110S/CAB-135S Art. 10115105/10115106

17

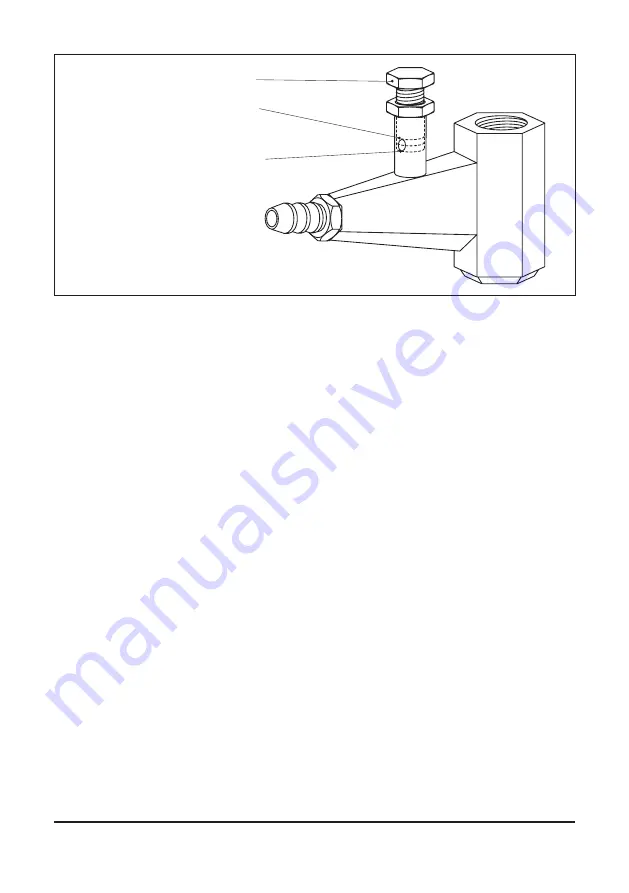

Picture 4.3.3

. Metering valve adjustment

Adjusting Screw

holes fully open

holes fully closed

Observe media flow through the clear media hose. Media should flow smoothly

and evenly through the hose. If the air exiting the nozzle pulses or if media does not flow

smoothly, the metering valve requires adjusting.

To adjust loosen the locking nut, and adjust the metering screw until the hole in the

metering stem is half-closed.

If pulsation occurs in the media hose, either media is damp and caked, or not enough

air is entering the media stream. While blasting, loosen the locking nut and slowly turn the

adjusting screw out (counter clockwise when viewed from the top) until the media flows

smoothly. Tighten the locking nut to maintain the setting. If media flow is too light, decrease

air in the mixture by turning the metering screw in (clockwise when viewed from the top)

covering more of the hole so less air enters the media hose. Tighten the locking nut to

maintain the setting.

4.3.4 Reclaimer static pressure

Correct static pressure varies with size of reclaimer and the size, weight and type of

media. Adjust reclaimer static pressure by opening (handle horizontal) or closing (handle

vertical) the damper on the dust collector inlet.

If the damper is not opened enough, the reclaimer will not remove fines, resulting

in dusty media, poor visibility, and possible media blockage in the conveying hose. If the

damper is opened too far, it may cause carryover (usable media carried into the dust

collector) and result in excessive media consumption. Open only as far as necessary to

obtain a balance of dust removal without media carryover.