2

N

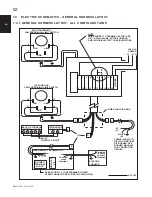

RED

YELLOW

BLUE

BLACK

WHITE

BLOWER MOTOR HARNESS

TERMINAL BLOCK IN BLOWER

MODULE

ELECTRIC FURNACE HARNESS

(NOT APPLICABLE FOR “WOOD ONLY” FURNACE)

12

3

H73.4

2

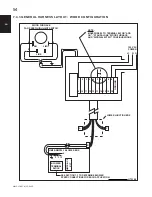

N

RED

YELLOW

BLUE

BLACK

WHITE

BLOWER MOTOR HARNESS

TERMINAL BLOCK IN BLOWER

MODULE

ELECTRIC FURNACE HARNESS

(NOT APPLICABLE FOR “WOOD/OIL” FURNACE)

12 3

H73.5

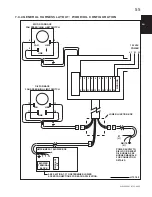

2

N

RED

YELLOW

BLUE

BLACK

WHITE

BLOWER MOTOR HARNESS

TERMINAL BLOCK IN BLOWER

MODULE

ELECTRIC FURNACE HARNESS

(NOT APPLICABLE FOR “WOOD ONLY” FURNACE)

12

3

H73.6

2

N

RED

YELLOW

BLUE

BLACK

WHITE

BLOWER MOTOR HARNESS

TERMINAL BLOCK IN BLOWER

MODULE

ELECTRIC FURNACE HARNESS

(NOT APPLICABLE FOR “WOOD/OIL” FURNACE)

12

3

H73.7

FOR WOOD,

WOOD/ELECTRIC

COMBINATIONS

(CHMF150)

(15,18,20 KW)

CHMF150

FOR WOOD/

OIL, WOOD/

OIL/ELECTRIC

COMBINATIONS

(CHMF150)

(15,18,20 KW)

FOR WOOD/

OIL, WOOD/

OIL/ELECTRIC

COMBINATIONS

(CHMF200)

(18,20,25 KW)

CHMF200

FOR WOOD,

WOOD/ELECTRIC

COMBINATIONS

(CHMF200)

(18,20,25 KW)

)

7.3.1 SELECTING AIR CONDITIONING BLOWER SPEEDS

NOTE

See air conditioner manufacturers speci

fi

cation for required air

fl

ow for given coil sizes. If speci

fi

cation not

available, use 400 CFM for every ton of cooling, as a general rule.

W415-1506 / A / 12.04.15

50

IOM

EN