21

COMUNELLO

®Copyright 2021 - All rights reserved

ENGLISH

4 INSTALLATION

4.1 PRELIMINARY CHECKS

For correct operation of the automation system, make sure:

• All the accessories are suitably sized.

• The door does not move autonomously when released in any position.

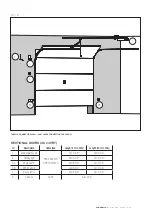

• The minimum and maximum clearances shown in figure 1 are complied with

• In the case of up-and-over doors ensure that the door panel does not interfere with the chain track. (FIG. 2).

• There are no points of stiffness throughout the entire opening or closing travel of the door.

4.2 APPLICATION LIMITS

Before installing the operator check that its specifications are within the application limits shown in the chapter “Product Technical

Specifications”.

4.3 INSTALLING THE RAMPART OPERATOR

4.3.1 INSTALLATION

• Arrange the two track sections for assembly. (skip this step if the track is supplied in a single length).

• Slide the drive head with sprocket into the track FIG. 3.

• Join the two track sections using the joint as shown in FIG. 4 (skip this step if the track is supplied in a single length).

• Bring the terminal with sprocket to the end of the track and fit the tensioner with spring to the track (FIG. 5).

• Tighten the supplied nut against the spring until the chain/belt is sufficiently taut (FIG. 6).

• Fit the drive lever and fixing bracket to the door with the guide trolley (lever "A" alone may be used) (FIG. 7).

• Insert the track support bracket over the track (FIG. 8).

• Secure the operator to the track using the screws and brackets supplied (FIG. 9).

• Secure the support brackets to the track holder bracket (FIG.10). The drilled plates can be cut to the required length. In the case

of direct ceiling mounting, do not use the supplied brackets.

• Fix the front bracket in a central position above the door. (FIG. 11).

• Assemble the track and front bracket fixed above the door using the supplied pin and cotter (FIG.12).

• Fix the track to the ceiling as shown in FIG. 13 and 14.

• Secure the drive lever to the door using the supplied pin and cotter (FIG.15).

• Tie on the manual release cord (FIG.16).

4.3.2 LIMIT STOP ADJUSTMENT

• Undo the limit stop and bring it to the required position FIG. 17.

• Lock the limit stop in position by tightening the screw.

4.3.3 MANUAL RELEASE

• To release the door and allow it to be opened and closed manually pull the cord tied to the sliding trolley in the guide track. (FIG.18).

• The door can now be moved manually .

4.4 SWING ARM INSTALLATION

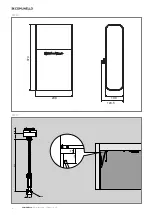

• To install the swinging arm, refer to the dimensions shown in FIG.21.

5 ELECTRICAL CONNECTIONS

The operator is supplied with a power cable for connection to the mains switchboard (suitably protected). For connection of

accessories (pushbuttons, selectors, photocells...) refer to the following heading (FIG. 19).

• Use only double insulated cables (sheathed cables) during the installation phase for both the connections in AC voltage (230 V)

and the ones in SELV safety extreme low voltage (flashing, photocells).

• Double insulation of cables has to be maintained up to the immediate proximity of terminals, unsheathing them exclusively in

proximity of terminals and they will have to be bonded by cable ties.

• Use only plastic raceways during the installation phase.

• Use separate raceways for the low voltage wirings (230 V) and for the ones in SELV safety extreme low voltage.

• Safety extreme low voltage conductors have to be physically separated (at least 4 mm up in the air) from the ones in AC voltage,

or they have to be adequately isolated with additional insulation with a thickness of at least 1 mm.

• Use FG7 2x1,5 mm2 cables or an higher category as power cord.

• Provide upstream of the mains supply of the automation a device that can assure an all-pole disconnection from the electrical grid

(with the 3rd category of overvoltage and with an opening distance of the contacts in each pole of at least 3 mm), in compliance

with the installation rules and directly connected to the power supply terminals.

Summary of Contents for RAMPART 1000

Page 2: ...2 COMUNELLO Copyright 2021 All rights reserved FIG 1 FIG 2 40 400 0 400 2800 mm 500 mm...

Page 3: ...3 COMUNELLO Copyright 2021 All rights reserved FIG 3 FIG 5 FIG 6 FIG 4...

Page 4: ...4 COMUNELLO Copyright 2021 All rights reserved FIG 8 A FIG 7 FIG 9 FIG 11 FIG 10 FIG 10...

Page 5: ...5 COMUNELLO Copyright 2021 All rights reserved FIG 14 FIG 12 FIG 13 FIG 15...

Page 6: ...6 COMUNELLO Copyright 2021 All rights reserved FIG 16 FIG 17 FIG 18...

Page 50: ...NOTES...

Page 51: ...51 COMUNELLO Copyright 2021 All rights reserved NOTES...