P M 13 7 9

10

Readjust

Controls And

begin welding

Do a Weld

Test

Adjust

Controls

Turn On Unit And

supply gas

(If Applicable)

Put On Personal

Safety Equipment

Install &

Connect

Equipment

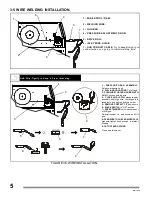

FIGURE 4-12 SECUENCE FOR SOLID WIRE AND FLUX CORED ARC WELDING.

FIGURE 4-13. SECUENCE FOR ALUMINUM WIRE WELDING.

Put On safety

equipment.

Adjust drive roll

Pressure at

minimum

Adjust hub

tension at

minimum

Readjust controls

and beging

welding

Do a test weld

Install & Connect

equipment using

"U" rolls

Turn on

equipment and

adjust gas at 30cfh

Adjust controls and

keep away GUN

from work piece.

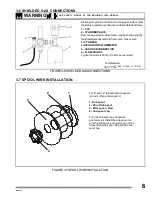

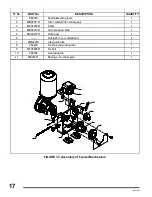

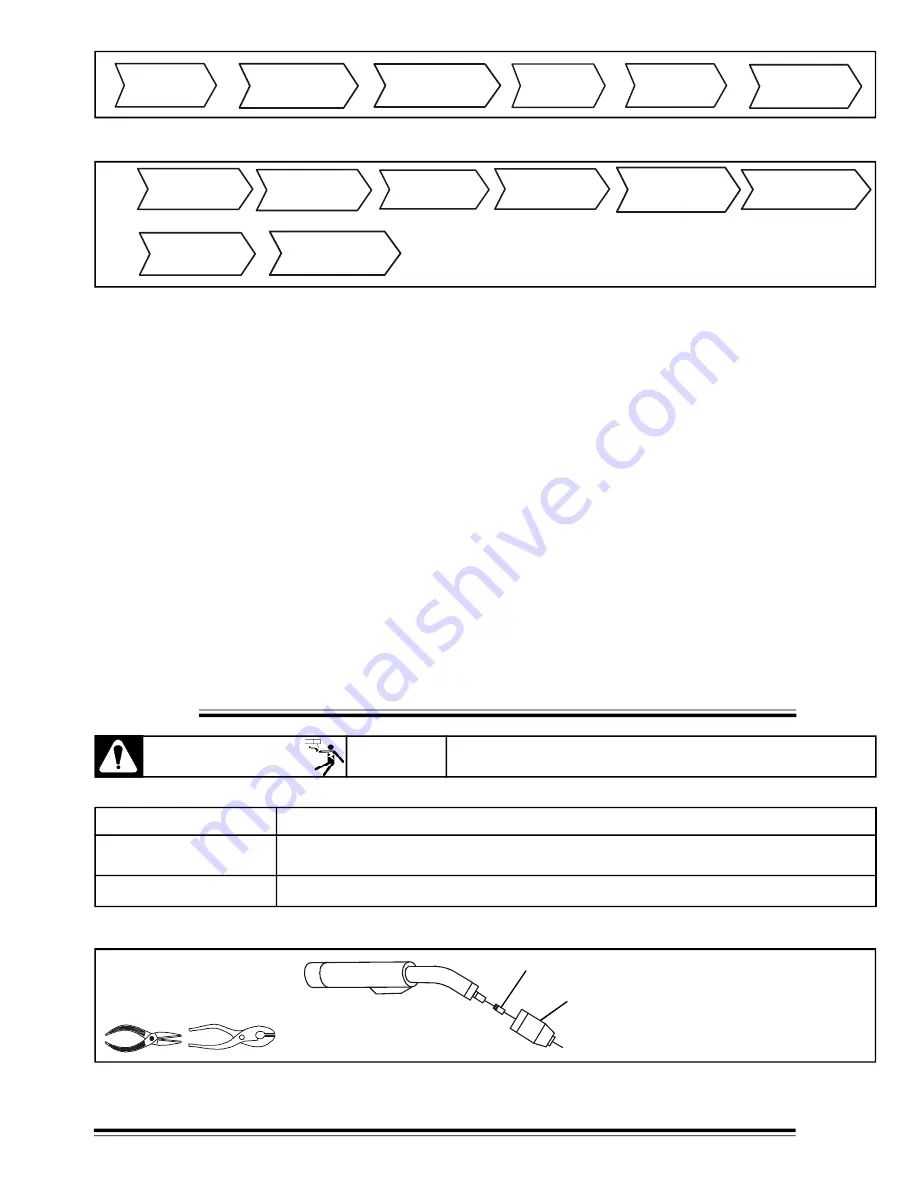

FIGURE 5-1. CHANGING CONTACT TIP.

Turn off and disconnect the unit.

1.- NOZZLE.

2.- CONTACT TIP.

Cut wire remaining

of the contact tip, remove Nozzle, remove

the contact tip and install one new.

Reinstall nozzle.

Tools Needed

2

1

5-1 ROUTINE MAINTENANCE.

TIME

Replace unreadable Labels ; Clean And Tighten Weld Terminals; Tape Or Replace Cracket

Weld Cable; Replace Cracket Parts (such as 14-Pin Cord,Gas Hose, Gun Cable).

Each 3 Months

Each 6 Months

MAINTENANCE

Blow Out Or Vacuum Inside; During Heavy Service Clean Monthly; Clean Drive Rolls.

5-2 CHANGING CONTACT TIP.

SECTION 5 MAINTENANCE &

TROUBLESHOOTING

WARNING

SEE SAFETY PREC AUTIONS SECTION