4.

Layout and Function

4.1.1 CO Option

The CMM monitors system air (air exiting the

purification system) for high levels of carbon

monoxide only while the compressor is

running.

This is controlled by two systems

comprising of a solenoid valve and auxiliary

contacts. When the motor contactor engages

it closes the auxiliary contact which sends a

signal to the CMM that the compressor is

running. Once the CMM receives this signal it

opens the supply air solenoid allowing air to

cross over the CO cell. The monitor has a built

in 5 second delay to allow the system air to

purge the ambient air in the CO cell housing

ensuring the user that the displayed reading

is accurately reading the system air free of

any ambient contamination.

The supply air is controlled by two regulators.

These regulators reduce the system high

pressure to 5 PSI that the CMM can accurately

determine CO levels. Set the first regulator to

100 PSI and the second to 5 PSI.

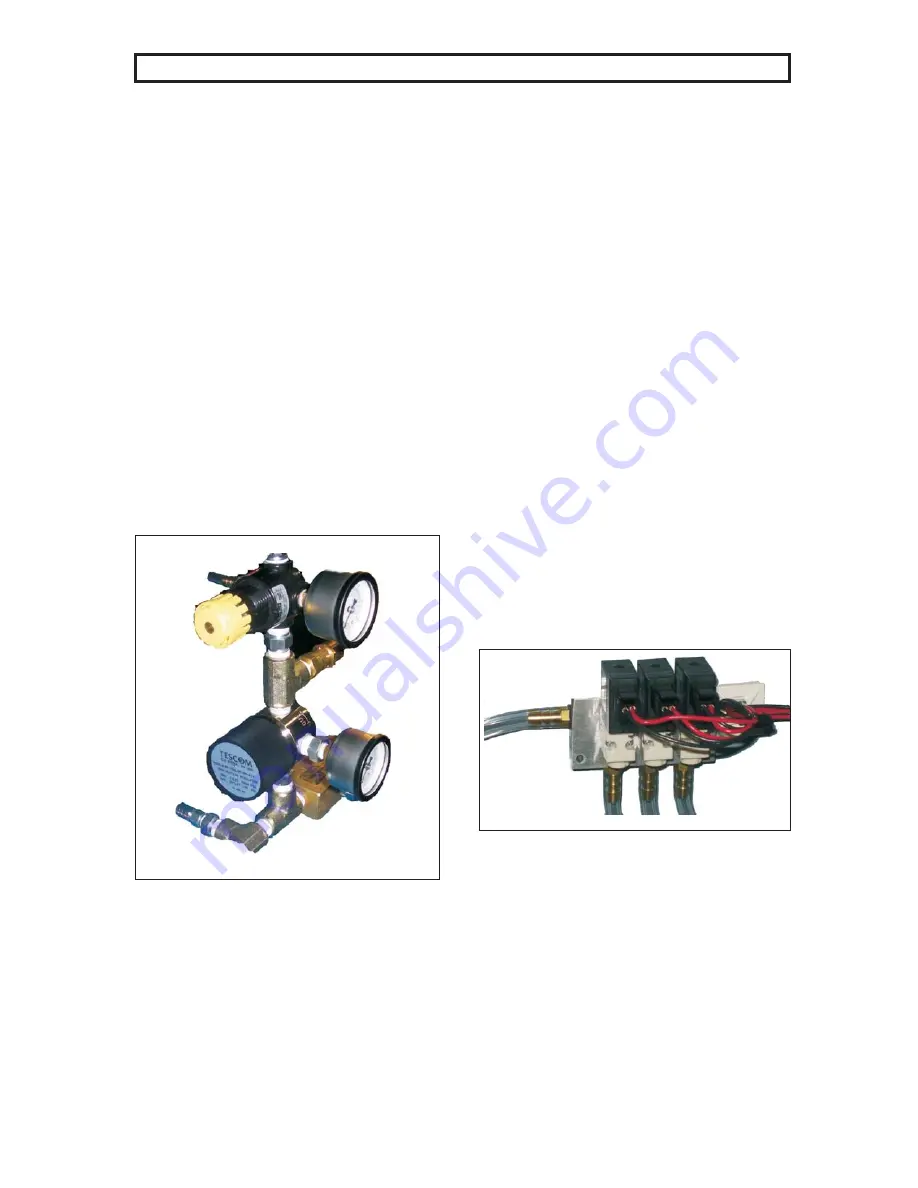

fig 4.1.1-1 CO Pressure Reducing Regulators

The CMM monitors supply air input to the CO

sensor by a small pressure switch mounted on

the CMM board.

If no pressure is detected

after a short amount of time the CMM will shut

the compressor down, alarm, and indicate no

CO pressure.

This safety ensures the user

that adequate flow to the sensor is available

for proper monitoring.

Excessive heat buildup can be detrimental to

the life and operation of the CO cell. Therefore

a red rubber hose has been added to direct the

air flow out of the upper control panel and

maintain a cool environment as much as

possible.

The CMM is equipped with a

temperature

sensor

that

detects

the

temperature inside the CO sensor housing to

ensure the cell does not see temperatures

above operating levels.

Calibration can be completed in a few simple

steps. The first is to turn on the zero and

twenty

PPM

calibration

cylinders,

select

calibration from the CMM menus and then

observe monitor for completion. (See Section

6.3.3) The first step in the calibration sequence

will turn on the 20 PPM calibration solenoid and

measure the cylinder for sufficient pressure to

calibrate. If insufficient pressure is observed

an alarm will sound, stop the calibration

process, and indicate the cylinder is empty.

The second operation will be to allow flow

across the CO cell for sixty seconds. Once this

time has elapsed the twenty PPM solenoid

closes and the sequence repeats with the 0

PPM calibration cylinder.

4-2

4.1.1.1 Solenoids - CMM Control Panel

Inside the CMM control panel are three small

solenoids as shown in fig. 4.1.1.1-1.

The solenoids control the flow of the pure air

and 20ppm calibration bottles, as well as, the

inlet supply air from the compressor.

To extend the life of the CO cell the CMM limits

the flow of dry air across the cell for only the

duration of the running compressor by

operating the supply air solenoid.

fig.4.1.1.1-1 Solenoid Valves