37

8. Servicing and maintenance

Important

The replacement of a single V-belt is not permit-

ted, always replace a complete V-belt set.

During the entire service life of the V-belt set, no

readjustment of the automatic V-belt tensioning

system will be necessary.

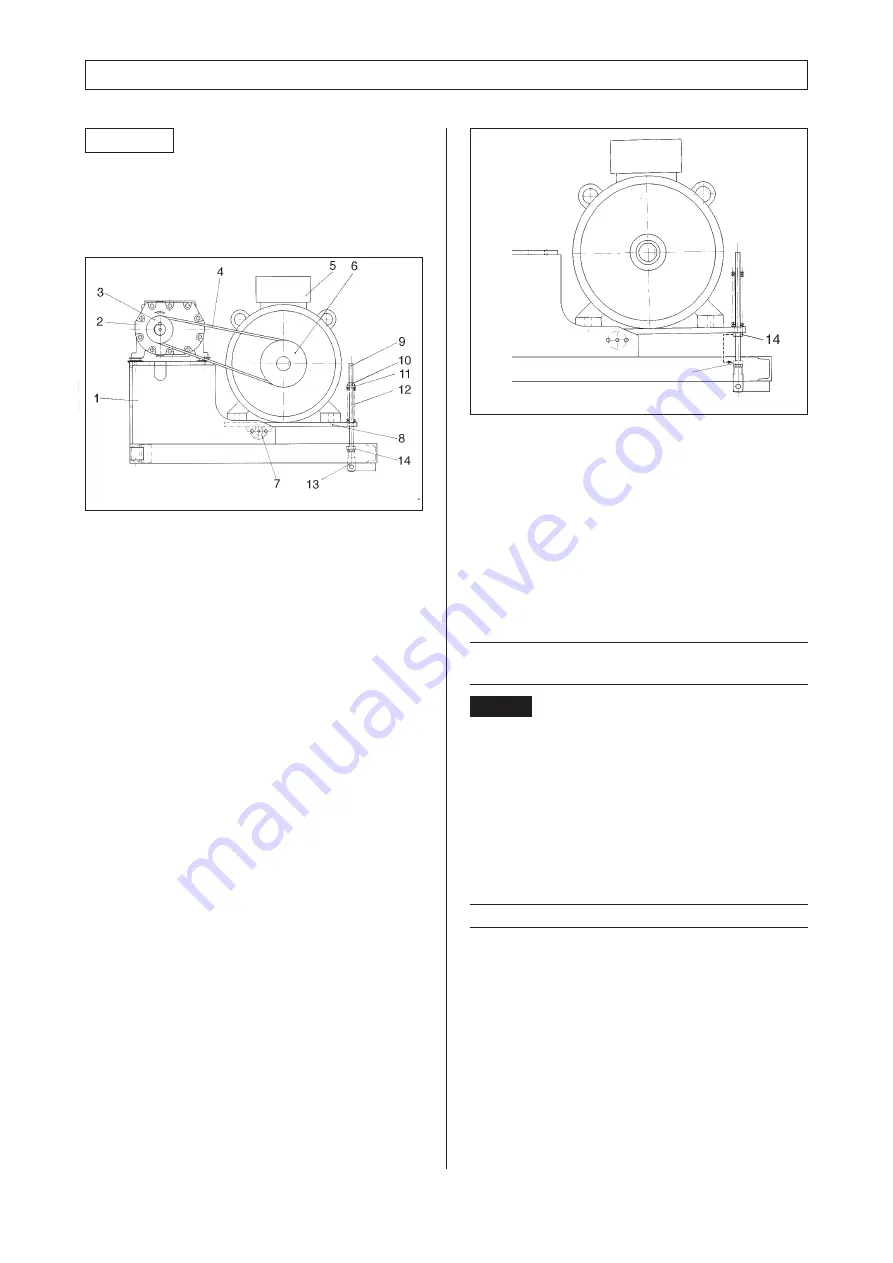

Fig. 26

1

Main frame of the drive

2

Compressor

3

V-belt pulley - compressor

4

V-belt set

5

Electric motor

6

V-belt pulley - electric motor

7

Bearing flange

8

Threaded rod

9

Distance sleeve

10

Clamping nut (self-locking)

11

Guide ring

12

Compression spring

13

Adjustment support

14

Nut

It is not permissible to loosen the bearing flange

screws (anti-vibration mount of the electric motor).

Any changes to the anti-vibration mount of the electric

motor can result in a drastic reduction in the service life

of the drive system.

The required pre-tensioning rate of the V-belt for each

screw compressor type is set in the factory.

For the adjustment after the first installation or a repla-

cement of the V-belt set, the compression spring has be

pretensioned. For this purpose, a blue marking is provi-

ded on the threaded rod.

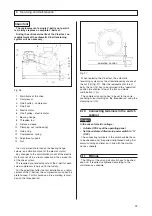

Fig. 27

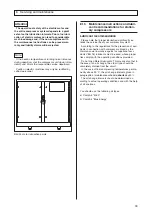

8.10

Connecting terminals in the switch

cabinet

When replacing the V-belt set, the automatic

tensioning system must be stressrelieved by means of

the nut (14) (fig. 27). After the replacement of the V-

belts, the nut (14) has to be returned to the "operation"

position (mechanical stop of the fork and clevis

combination (13)).

The compression spring has to be set to the corre-

sponding colour marking on the threaded rod using the

clamping nut (10).

Danger

.

In the case of electric voltage :

• Actuate OFF-key at the operating panel

• Set the customer-fitted main power switch to "O"

(OFF)

The connecting terminals in the switch cabinet have

to be checked and, if required, retightened during first

commissioning and later on in line with the mainte-

nance schedule.

8.11

Fittings

The fittings of the air and oil circuits have to be chek-

ked and, if required, retightened according to the

maintenance schedule.

operating position