39

8. Servicing and maintenance

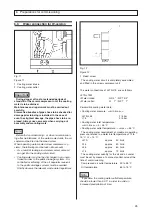

Bild 24 motor lubrication points

Attention

The operational safety of the electric motor and

the entire compressor system depends to a great

extent on the lubrication intervals. Poor of no lubri-

cation of electric motors can Iead to considerable

machine damage and, if the non-compliance with

the maintenance instructions can be proved, war-

ranty and liability claims will be rejected.

Note

If the bearins temperature or running noise increases

during operation, shut the compressor unit down imme-

diately and inform the responsible service departmen.

Faults on electric machines may only be rectified by

skilled personnel.

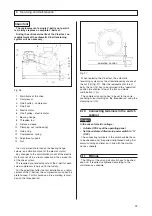

8.13

Maintenance instructions and lubri-

cant recommendations for station-

ary compressors

Lubricant recommendation

Please note that proper lubrication significantly ex-

tends the service life of your compressor system.

According to the regulations for the prevention of acci-

dents in connection with compressors (issed by the

German social insurance against occupational acci-

dents VBG 16) lubricants must be used, whose proper-

ties comply with the operating conditions provided.

Do not mix different lubricants. This means also that in

the case of an oil change, the old oil type should be

completely drained from the circuit.

In the case of final compressing temperatures perma-

nently above 90 °C, the oil change intervals given in

paragraph 8.3 (maintenance schedule)

shorten

by 50 %.

The oil change intervals should be determined ac-

cording to actual operating conditions and with the help

of oil analyses.

You should use the following oil types:

a) CompAir "4000“

b) CompAir "Blue Energy“