COMPA TECH S.r.l.

Web: www.compasaw.com - E-mail: [email protected]

Tel. (+39) 059 527887 - Fax (+39) 059527889

- 33 -

ENGLISH

Operator’s handbook

8. MAINTENANCE

The machine does not require any particular

lubrication because the moving parts are selfl u-

bricating.

It is a good idea to periodically check the condi-

tions of the power supply cords and replace them

if they are broken, or even worse if the internal

wires are showing.

Always keep the machine handle clean to prevent

accidental slipping when using it.

It is also important to always keep the support

surfaces and guide squares clean, possibly equip

the machine with a suction system; the machine

is already set-up with a conveyor and connection

openings.

Carefully clean the machine after use with jets of

air or a dry brush and remove any glue or other

material from the work surfaces.

To obtain excellent results it is necessary to pe-

riodically check the conditions of the blade and

have it sharpened as soon as it is necessary.

Every 100 hours of operation check the blade

rotation stop time using a simple chronometer.

If the time is over 5 seconds, carry out the

adjustment described in the paragraph below.

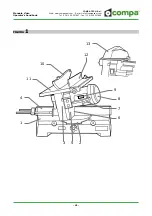

8.1 Adjusting the blade stop time

If the blade rotation stop time does not correspond to

the established values, adjust it as described below:

remove the motor fan cover using a screwdriver

and pulling it towards the outside.

push the motor fan L a few millimetres towards

the outside and lock the set screw at the same

time (fi g.35).

replace the motor fan cover by pushing it towards

the motor.

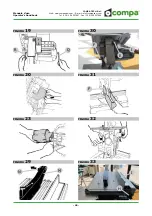

8.2 Adjusting the arm return spring

The correct functioning of the spring device foresees

the return of the arm to the upper position (from

end cut position) without any intervention by the

operator at a relatively contained speed in order not

to trigger the risk of an overturning.

ATTENTION! no adjustment must be car-

ried out by not suitably trained persons or

expressly authorized by Compa Tech. S.r.l.

In case the sawblade carrying arm returns to the

upper position as per above mentioned procedure,

make sure that:

the suction pipe is no obstacle to movement;

the mobile parts of the sawblade carrying arm

do not collide with the external structures (the

conditions of positioning are respected);

the suction pipe mantains its expected fl exibility;

all the mechanical parts are clean and free from

chips.

Overloading the spring could trigger unfo-

reseen and unforeseeable strains that could

lead to its collapse.

No blame can be put on Compa Tech. S.r.l. for any

improper adjustments carried out by not expressly

authorized staff.