COMPA TECH S.r.l.

Web: www.compasaw.com - E-mail: [email protected]

Tel. (+39) 059 527887 - Fax (+39) 059527889

- 31 -

ENGLISH

Operator’s handbook

6. USE

6.1 Preliminary checks

As soon as the machine is unpacked, before starting

the motor, unlock the saw-motor arm as follows:

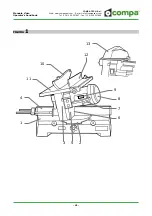

Pull knob N (fi g. 16) out and put the

sawmotor arm to its standby position.

Make sure that the blade guard moves

correctly and scrupulously check that the

blade is not hindered by anything by rota-

ting it by hand.

ATTENTION: in order not to jeopardise

the stability of the machine during cutting

operations, it must be secured to a stable

structure, using the holes in the base (see

point 5.3).

6.2 Lower part cutting operation

The cutting operation in the lower part is carried out

as follows:

ATTENTION: Use the vices to fi rmly clamp

the two sides of the workpiece if its shape

and size are such as to make it diffi cult to

safely fi x them both on the table and

against the rear stop. It is forbidden to

carry out cuts on workpieces which are

badly laid or not fi rmly fi xed. (see Fig. 41-

41A).

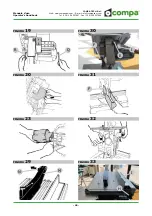

take the handle, press lever E (fi g.30) and slightly

lower the saw-motor arm. Press the motor start

button “I” (fi g.30) located on the handle and wait

for the motor to reach operating rpm.

securely fi x the material to be cut to the work

base keeping it pushed with a clamp against the

edges of the support so that it does not move

during the cut (fi g. 15).

use the handle to lower the blade until it comes

into contact with the material to be cut, then

gradually push until completing the desired cut.

ATTENTION: pushing harder on the

handle during the cut does not necessarily

mean a faster cutting speed. On the con-

trary, it may cause excessive overloading

of the motor and less effi cient operation

(the motor may breakdown and the blade

may get damaged).

when you fi nish cutting turn off the motor by

releasing the switch and put the saw-motor arm

in its standby position and make sure the arm

lock triggers.

when you fi nish cutting turn off the motor by

pressing button “I” (fi g.30) and put the saw-

motor arm in its standby position and make sure

the arm lock triggers.

Tips for cutting at 90° and 45° see fi g. 6B, 6C.

6.3 Cutting on the upper surface

Only for models JET when working on the

upper surface you must mount the lower

guard supplied with the machine. Always

use the piece pusher during cutting opera-

tions on the upper surface.

To mount this guard proceed as follows:

if the saw-motor arm is locked in the lowered

position, raise it (see point 5.1) and insert guard

F (fi g. 31) in the support guides. Lower the saw-

motor arm and lock it centring the previously

mounted guard.

The cutting operation on the upper surface is carried

out as follows:

release knob N (fi g. 29) of upper guard M.

loosen knobs G (fi g. 32), set the desired cutting

height based on the dimensions of the piece to be

processed by raising or lowering the upper sur-

face by acting on the knob F (Fig.30). Once you

have obtained the desired position, lock knobs G

starting with the one closest to the operator.

loosen knobs H (fi g. 33) and adjust upper square

I in the position required for the desired cutting

width (indicated on the millimetre ruler printed

on the upper surface) and lock using knobs H.

Make sure that the upper square is parallel to the

side of the blade.

check the operation of the upper saw guard M

(Fig. 29) and correct locking of the upper square

I (fi g. 33).

start the motor using the start switch “I” and put

the piece to be cut at the beginning of the surface