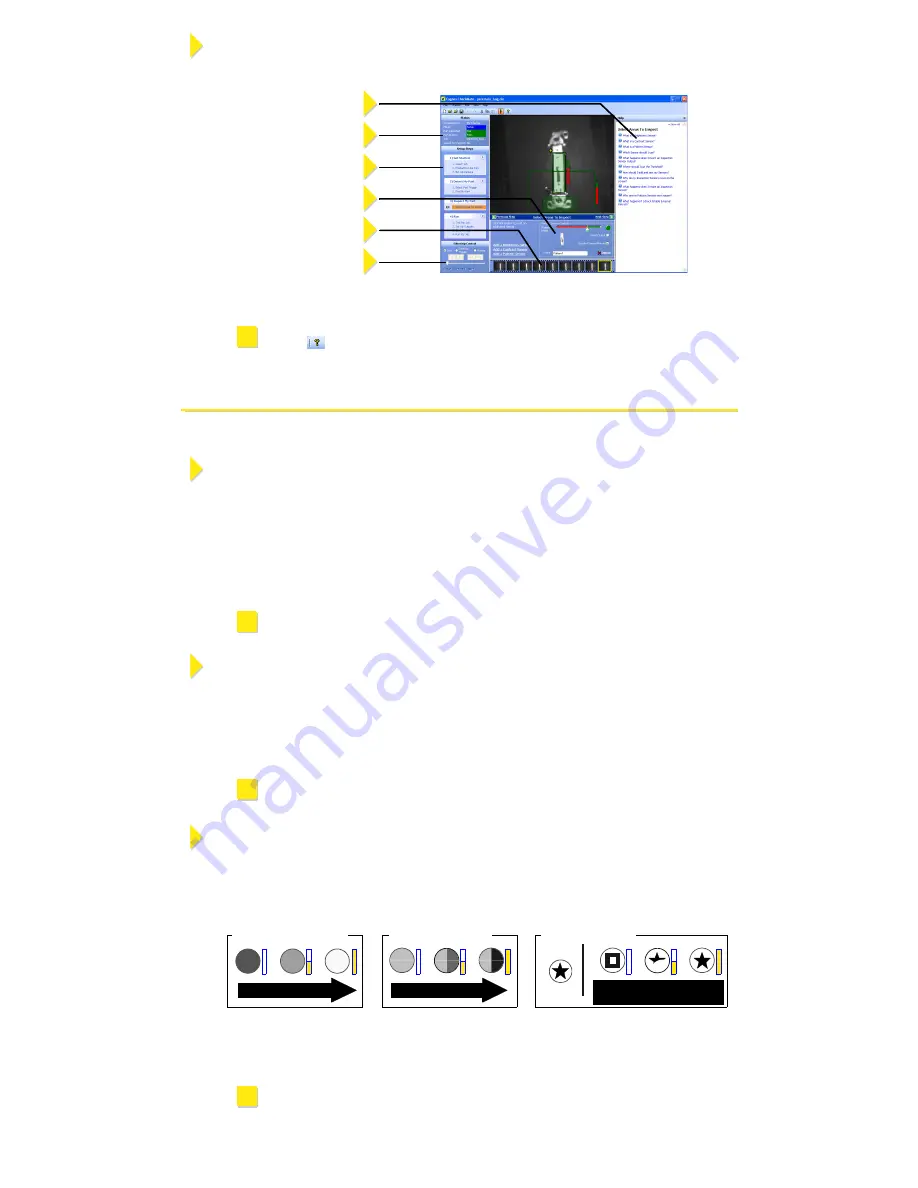

Start the CheckMate Software

Start CheckMate by double-clicking on the CheckMate icon. (The first time that you start

CheckMate, it may take a moment before your PC recognizes Checker.)

CheckMate always displays a list of questions and answers related to the current state of

CheckMate.

Setting Up Your Job

A Checker

job

contains all of the information that Checker needs to check your part. You set up a

Checker job in four simple steps using CheckMate.

1. Get Started

•

Create a new job.

•

Enter your line speed and direction.

•

Place a ruler at the same distance from Checker as your part will be, and enter the size of

Checker’s field of view.

If you specify a horizontal machine direction, this size is the distance between the left and right

edges of what Checker can see; if you specify a vertical machine direction, the size is the

distance between the top and bottom of what Checker can see.

•

Adjust the image brightness and focus Checker on your part.

Detect My Part

Before Checker inspects your part, it must detect that your part is present. Checker can detect your

part in two ways:

1

Checker can detect parts using a

Part Finding Sensor

. Simply create a Part Finding Sensor

and place it over a part feature that Checker can always see.

2

You can use an external photoelectric sensor to tell Checker that the part is present. Checker

uses the rising edge of the input signal.

Inspect My Part

Create an

Inspection Sensor

for each part feature that you want to check. The result of an

Inspection Sensor can be

pass

or

fail

. The results of all Inspection Sensors must be

pass

for

Checker to pass your part. If the result of any Inspection Sensor is

fail

, Checker will fail your part.

Checker provides three types of Inspection Sensors:

Brightness Sensors

detect bright features;

Contrast Sensors

detect high-contrast features; and

Pattern Sensors

detect matching patterns.

To create an Inspection Sensor, click on the feature to check, then adjust the Sensor’s threshold so

that good parts are above the threshold and bad parts are below it. For Brightness and Contrast

sensors, you can adjust the Sensor’s range and sensitivity to better distinguish between good and

bad parts.

For detailed information on how Checker works and how to use CheckMate, click

on the

button to open the User’s Manual.

Checker is shipped with its focus unlocked. If you have tightened the focus lock,

make sure to loosen it before adjusting the focus.

If you use both an external photoelectric sensor and a Part Finding Sensor, both

the photoelectric sensor and the Part Finding Sensor must indicate that the part

is present before Checker will inspect the part.

You can invert the result of an Inspection Sensor if you need to detect dark

features instead of bright features, low-contrast features instead of high-contrast

features, or mismatched patterns instead of matching patterns.

3

Checker Status

Job Setup Steps

Filmstrip Control

Filmstrip

Controls

Questions and Answers

!

1

!

2

!

3

Brightness Sensor

Contrast Sensor

Pattern Sensor

Brighter

More contrast

No

match

Match

Partial

match

!

Summary of Contents for Checker 101

Page 1: ...Quick Reference...