51

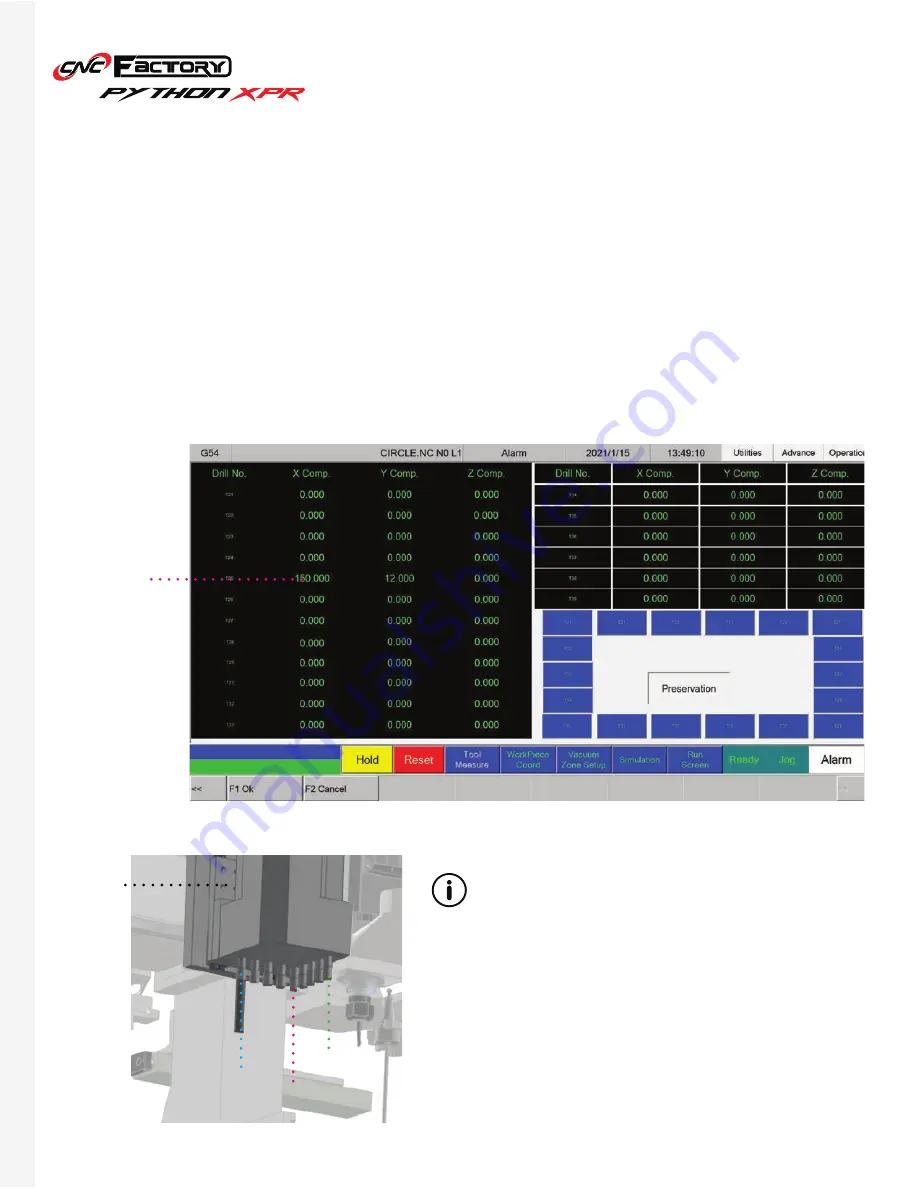

You can adjust the drill block offset to indicate the direction (and by how much) the machine needs to travel in

order for the drill block to bore at the same location where the spindle did previously.

1. In the [Operation] page, click [JOG].

2. Go to the [Utilities] page and click [Block Offset].

3. Highlight the field you want to adjust, type in the new value and press [Enter].

4. Once the number has changed, press [Preservation] to save.

5. If prompted for a password, type in “521” and press [F1 Ok].

Adjusting Drill Block Offsets

[requires upgrade]

We recommend adjusting T25 first and then just use

the values you placed there as a reference for other

numbers. Based on the physical layout of the drill

block:

• T25, T26, T27, T28, T29 should have the same X-axis

value

• T21, T22, T23, T24, T25 should have the same Y-axis

value.

• The distance between tool slots is 32mm.

For advanced users:

Adjust T25

first

T25

T29

T21

Drill

block

Summary of Contents for PYTHON XPR

Page 1: ... U S E R G U I D E ...