Page 6

Installation and Assembly Guide:

Norms and Directions

•

It is the responsibility of the installation engineer that he has the necessary training and authorisation

to install the boiler. The size of the boiler should be based on the heating needs of the house rather

than the size of the fuel container.

The installation must fulfill the requirements described in the directions of the

Health and Safety at

Work Act 1974, iincluding the following regulations: The Electricity at work Regs 1989, The Provision

and Use of Work Equipment Regs 1998, The Personal Protective Equipment Regs 1992,

The Fire Precautions (Workplace) (Amendments) Regs 1999, The construction Design and

Management Regs 1994. Current Institute of Electrical Engineers regulations. “The Pressure

Equipment Directive 97/23/EEC” and UK Building Regulations 2000 (as amended). See in particular

the following approved documents:

A: structure 2004 + amendments

B: fire safety 2000 e amendments

F: ventilation 2006 edition

J: combustion appliances and fuel storage systems 2002 edition

J: Guidance and supplementary information on the UK implementation of European standards for

chimneys and flues 2002 edition

L1A; L1B; L2A;L2B: Conservation of fuel and power 2006 edition.

M: Access to and use of buildings 2004 edition

P: Electrical Safety – Dwellings – 2006 edition

•

If the boiler is used for burning straw, the installation must furthermore fulfill the requirements

described in the specific directions of The Health and Safety at Work Act 1974

•

All smoke pipes must have an uphill gradient of minimum 1 %, and all joints must be tight. Never use

a smaller diameter smoke pipe as the boiler outlet pipe. Always use elbows with a bending and flap as

bent joints, as they provide the best flue.

All smoke pipes must be insulated, also when the boiler

is used with stoker feeding.

•

The combustion must not be carried out until the boiler is installed and fully connected.

•

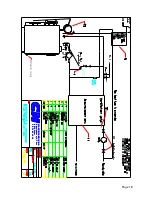

A probe must always be installed on the boiler, and the return pipe (pages 9/11) must always be

minimum 60° C during operation. See the assembly guide drawing.

•

If the right physical conditions are present, the boiler may be installed on a base (approximately

400 mm high) to make the operation and removal of ashes easier.

Open or closed system

•

CN boilers type 80 and type 120 are approved for installation as open or closed systems.

•

When used as a closed system (with pressure expansion) and open system with a height above 5

meters, the boiler must be equipped with a cooling spiral and a thermal over temperature valve

(pages 7 & 8).

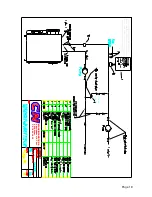

Safety valve requirements in closed systems

•

With boilers > 60 kW every boiler must have at least 2 safety valves. The safety valves must be able

to, in combination at the chosen blow-off pressure, blow off at least 1.5 times the boiler heat yield in

the form of steam. They must, however, have a minimum internal diameter of 20 mm.

•

The inlet and outlet hoses of the safety valves must be of sufficient dimensions for the capacity of the

safety valves not to be noticeably reduced. The inlet pipe must not contain blocking devices, pumps,

boiler mountings, restrictions or water sacks.

•

All inlet and outlet hoses to and from safety valves must be run through pipes approved for 120 °C

and minimum 10 bar over pressure.

Summary of Contents for 120

Page 17: ...Page 17 ...