Page 8

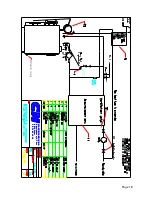

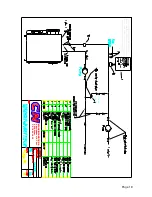

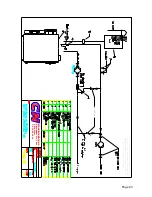

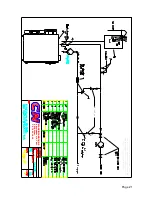

For installation with operational pressure >0.5 bar and pressure expansion, principle diagram pages

17 & 19 must be used

•

If the operational pressure of the vessel exceeds 0.5 bar over pressure, the boiler unit (the installed

boiler including fittings and safety equipment) is covered by the Pressure Equipment Directive

97/23/EEC ”Installation of pressurised equipment”, which requires that the boiler unit must fulfill

certain essential safety requirements regarding the safety equipment of the boiler etc.

The boiler

must be fitted with a cooling spiral amongst other things

The boiler including fittings and safety equipment must be installed in accordance with the principle diagrams

on pages 17 and 19. The engineer must test the safety equipment in accordance with the section "Testing

the safety equipment" before the system is handed over to the user. The following fittings and safety

equipment etc. must, in accordance with the above-mentioned principle diagrams, be installed in the boiler

unit in order to be covered by the CN Maskinfabrik A/S Construction Test Certificate:

The boiler must be installed with pos. nos. 1, 2, 3, 4, 6, 7, 9, 10, 13 (drawings pages 17 & 19)

Description

Type / Requirements

Draw. Pos

nos.

Supplier

Shunt valve

TA type TRV 300

1

CN (supplied)

Oper. thermostat

BS components type NTC-2322

2

CN (supplied with stoker)

Overheating thermostat

Honeywell type L6188

3

CN (supplied with stoker)

Boiler thermometer

0-120 degrees

4

Installation engineer

Pressure gauge

(manometer)

0-3 maximum 5 bar, red marks at 2.5 bar

4

Installation engineer

Pressure expansion

vessel

CE labeled minimum 4 % of total system

water volume (see table below)

6

Installation engineer

Safety valve

CE approved

2 pces., 2.5 bar, clearance minimum 20

mm

7

Installation engineer

Cooling spiral

CN 80:

CN120:

Wieland heat exchanger type WRK 13

Wieland heat exchanger type WRK 13

9

9

CN (supplied)

Safety thermostat

Honeywell type TS130, CE approved

10

CN (supplied with stoker)

Water shortage protection RT 200 Pressostat

13

Installation engineer

NOTE:

•

The system must have a membrane type expansion vessel with airbag. The expansion vessel must

have a durable and solidly fastened rating plate which clearly states Manufacturer, Volume in litres,

Test Pressure in bar and Initial Pressure in bar

•

The expansion hose between the expansion vessel and the rest of the system must not be less than

25mm.

•

Safety valve

: The safety valve must be installed in accordance with the directions of The Health and

Safety at Work Act 1974.

•

Expansion vessel

:

Expansion vessels

: The vessel must be installed in accordance with the

directions of The Health and Safety at Work Act 1974.

•

Size of expansion vessel closed system:

Calculation of pressure expansion

Water expansion in % from 10 °C

Average temperature

°C

%

60

1.7

70

2.3

80

3.0

90

3.6

100

4,4

Summary of Contents for 120

Page 17: ...Page 17 ...