23

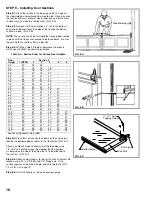

Lock the door in the down position securely using door lock

or locking pliers. This must be done to prevent the door

from prematurely opening which could cause an injury.

NOTE:

You need an assistant in Step 15-6. If your garage has

only one entrance, be sure you, the assistant, and the tools you

need are inside before you lock the door. Your door will have

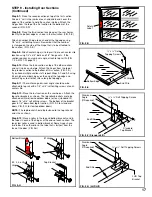

either one or two torsion springs. Each torsion spring consists of

spring coils, stationary cone, and a winding cone (FIG. 15-D).

The spring coils are color coded depending on the spring size

and the

winding cone

is color coded separately, either

red

or

black.

The color on the winding cone is to help identify on which

side of the door the spring is to be used.

NOTE:

Black winding cone torsion springs are used on the right

side of the door and red winding cone torsion springs are used

on the left side of the door when viewing the door from the inside

looking out. Failure to install the torsion springs on the correct

side will cause your door to function improperly and could result

in serious injury.

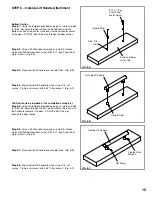

Step 15-5:

If door has low headroom front mount setup skip to

Step 19-1. Slip the torsion springs onto the spring tube, the

red

winding cone on the

left

end, the steel center bearing, center

bearing plate, and the

black

winding cone torsion spring on the

right

end (FIG. 15-E). Cable drums go on next, the

red

drum on

the left, and

black

drum on the right. The set screws on the

drums face the springs.

Spring anchor bracket secures the springs to the wall. You

must fasten securely with red-colored fasteners. Never

remove spring anchor bracket when springs are wound.

Step 15-6:

With an assistant, lift the complete torsion spring tube

assembly and slide the ends of the tube into the bearing on the

end bearing plates. With the tube level, mount the center bearing

plate to the center anchor pad using (2) 5/16" x 1-5/8" red-

headed lag screws. Drill 3/16” pilot hole for each lag screw.

Important:

These pilot holes must be no closer than 1-1/2" from

the sides and ends of the wood anchor pad.

Step 15-7:

Connect the spring(s) to the center bearing plate

using (2) 3/8” x 1” hex bolts and nuts for single springs or (2) 3/8”

x 1-5/8” hex bolts and nuts for double springs. (FIG. 15-F)

Step 15-8:

Bring up the left cable between the wall and roller

shafts to the cable drum. Attach cable by placing in the notch on

the cable drum. Turning the cable drum and sliding it up tight

against the end bearing plate to remove the cable slack.

Make

sure the cable follows the grooves in the cable drum.

The

set screws on the cable drum should be tightened with a 3/8"

box wrench while holding the cable taut. (

Caution:

Set screws

should be turned from ¾ to one full turn after they have made

contact with the tube.) Clamp locking pliers on to the torsion

spring tube to maintain tension on the cable. Repeat this

procedure on the opposite side.

FIG. 15-D

FIG. 15-E

FIG. 15-F

Winding Cone

Spring Coil

Stationary

Cone

Red Cable

Drum

Red Winding

Cone

Right Wound

Spring

Steel Center

Bearing

Center Bearing

Plate

Left

Wound

Spring

Black Winding Cone

Black

Cable

Drum

3/8” x1-5/8”

Hex Head Bolts

3/8” Hex

Nuts

Center Bearing Plate