19

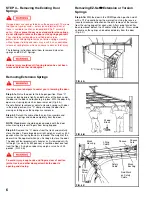

STEP 11 – Assembling and Installing

the Vertical Track

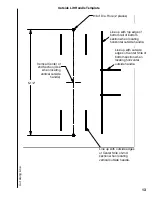

Before assembling brackets to vertical track be sure to read

Step 11-1 and Step 11-2. Refer to illustration for placement of

brackets on track.

NOTE:

Brackets may already be riveted in place. If additional

adjustment is required, the rivets can be drilled out and the

brackets can be reattached with track bolts and flange nuts

(available through the toll-free Consumer Services number, see

outside cover).

To avoid installation problems that could result in injury or

property damage, use only track provided with new door.

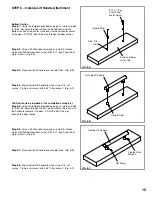

Step 11-1:

Loosely fasten the track brackets to the vertical

track using one 1/4" x 5/8" track bolt and 1/4" flange nut as

shown with the head of the bolt inside the track. There are

two sizes of brackets for 7’ high doors, and three sizes for 8’

high doors. The shortest track brackets should be installed ten

inches from the bottom of the track with the flange facing the

flat side of the track, one on the left and one on the right. The

next larger sized pair of brackets should be installed centered

on the track. If you have an 8’ high door, the remaining pair

of brackets should be installed ten inches from the top of the

vertical track. The flat side of the track goes toward the wall.

(FIG. 11-A)

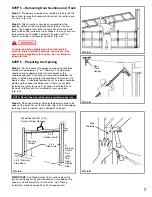

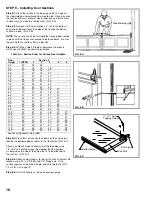

Step 11-2:

Loosely attach the flag bracket to the top of the

track with two 1/4" x 5/8" track bolts and 1/4" flange nuts with

the head of the bolts in the track. Make sure to place bolts and

nuts in correct holes (FIG. 11-B, See FIG. 11-C for bracket

placement).

(Refer to FIG. 11-B to determine proper bolt placement.)

NOTE:

If additional adjustment is required, horizontal slots in

flag brackets can be used for attachment to vertical track.

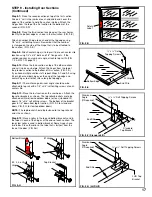

Step 11-3:

Place the track over the rollers on the door. Move

the track close to the door so that the rollers are all the way

into the hinges. Do not force the track too tightly or the door

will bind. This should leave about 1/2" between the edge of the

door and the track. Pilot holes of 3/16" are required at each

lag screw location before installing the lag screw. Lift track

about 1/2" from the floor and fasten the flag bracket and track

brackets to the jamb with 5/16" x 1-5/8" lag screws. The flag

bracket requires three screws, one each in the top, middle, and

bottom holes. Do this for both sides of the door. When the track

brackets and flag brackets are securely fastened to the jamb,

tighten the track bolts and flange nuts connecting the flag

brackets to the tracks. (FIG. 11-D)

NOTE:

The tops of the vertical tracks must be level with

each other. Check this by measuring from the top of the door

sections to the top of the track on both sides. If they are not

equal, cut some material off the bottom of one track to lower it

or raise the other track.

Do not raise the vertical track beyond the bottom rollers

on the bottom section of door.

NOTE:

Do not attach any brackets directly to drywall. All track

brackets, flag brackets, and spring brackets should only be

attached directly to wood jams.

FIG. 11-A

FIG. 11-B

FIG. 11-C

FIG. 11-D

1/4" Flange

Nut

1/4" x 5/8”

Track Bolt

Wall

Side

Top View

Left Side

Note: Use One

Track Bolt In Slot

1/4" Flange Nut

Use These

Two Holes

1/4" x 5/8”

Track Bolt

Top

Bottom

Shorter

Track

Bracket

Right Hand

Vertical

Track

Assembly

Longer

Track

Bracket

Flag Bracket

Left Hand

Vertical Track

Assembly