PREFACE

Make sure all blast operators are properly trained and suitably attired with a blast suit, safety boots, leather gloves, respiratory and hearing protection. Every day before start up,

check all equipment components, including piping, fittings, and hoses, and valves, for leaks, tightness, and wear. Repair or replace as needed. Use the following checklist.

1. PROPERLY-MAINTAINED AIR COMPRESSOR

sized to provide

sufficient volume (cfm) at given pressure for nozzle and other tools. ADD 50%

volume (cfm) reserve to allow for nozzle wear. Use large compressor outlet and

air hose (at least 4 times the nozzle orifice diameter). For oil-lubricated

compressors, the employer shall use a high- temperature or carbon monoxide

alarm, or both, to monitor carbon monoxide levels. If only high-temperature

alarms are used, the air supply shall be monitored at intervals sufficient to

prevent carbon monoxide in the breathing air from exceeding 10 ppm. Follow

the manufacturer’s checklist and maintenance instructions.

2. BREATHING-AIR COMPRESSOR

(or oil-less ambient air pump)

capable of providing Grade D quality air, located in a dust free area. Read # 1

above.

3. CLEAN, PROPERLY-MAINTAINED NIOSH-APPROVED SUPPLIED-AIR

RESPIRATOR

worn by blast operators, and other workers exposed to blast dust.

Make sure all respirator components are in place — all lenses, inner collar, and

cape. Thoroughly inspect all components for wear. The NIOSH approval (approval

number is listed in the owner’s manual) is for a complete assembly from point of

attachment on the CPF (sorbent bed) filter to the complete respirator. Substitution of

any part voids the NIOSH approval.

4. CARBON MONOXIDE MONITOR/ALARM

installed at the CPF filter or

inside the supplied-air respirator for monitoring for the presence of deadly CO gas

and warning the operator(s) when the CO level reaches an unacceptable level.

When an ambient air pump is used for breathing air, a CO monitor provides a

measure of safety. Read # 1 above.

5. BREATHING-AIR FILTER (OSHA-REQUIRED

sorbent bed filter) for

removal of moisture and particulate matter in the compressed air breathing-air

supply. Monitor the condition of the cartridge and replace when odor is detected or

at 3 month intervals, whichever comes sooner. The breathing air filter does NOT

detect or remove carbon monoxide (CO). Always install a CO monitor/alarm.

6. BLAST MACHINE

(bearing U or UM stamp, National Board Number, and

Maximum Working Pressure) sized to hold a 30-minute abrasive supply. Examine

pop-up valve for alignment. Check piping, fittings, screens, valves for tightness,

leaks, and wear. Always ground the machine to eliminate hazard of static shock.

Install a blast machine screen to keep out foreign objects. Use a blast machine

cover if left outdoors overnight. Never exceed the maximum working pressure of the

vessel.

7. AIR LINE FILTER

(moisture separator) installed as close as possible to the

blast machine inlet and sized to match the size of the inlet piping or larger air supply

line. Clean filter and drain often. Damp abrasive causes operational problems.

8. REMOTE CONTROLS

are required by OSHA and must be in perfect

operating condition. Test and check all components to ensure all parts are present

and fully functional. Use genuine replacement parts. NEVER mix parts from different

manufacturers. Never use welding hose for remote control hose.

9. BLAST HOSE

should have an inside diameter sized to suit the blast nozzle.

The ID should be three to four times the size of the nozzle orifice diameter. Blast hose

should be arranged in as straight a line as possible from the blast machine to the

work area, avoiding sharp bends.

10. COUPLINGS AND NOZZLE HOLDERS

should fit snugly on the hose and

be installed with manufacturer recommended screws. Coupling lugs must snap firmly

into locking position. Gasket must always be used to form a positive seal, and cotter

pins must be installed. Replace gasket when wear, softness or distortion is detected.

Check nozzle holder for thread wear; replace at any sign of wear. Install safety cables

at all connections.

11. NOZZLE

orifice size should be checked and nozzle replaced when worn

1/16” from original size. (No. 5 nozzle has 5/16” orifice diameter; replace when it

measures 3/8”). Threads should be inspected daily for wear and nozzle should be

replaced when wear is detected. Always use a nozzle washer.

12. ABRASIVE

must be a material specifically manufactured for blasting. It

should be properly sized for the job. Check material safety data sheet for free-

silica, cyanide, arsenic, lead and other toxins and avoid use when these toxic,

harmful substances are present.

SURFACE TO BE BLASTED

should be examined for hazardous substances.

Take appropriate protective measures as required by OSHA to ensure the blast

operator, other workers in the vicinity, and any bystanders are properly protected.

©Clemco Industries Corp., Stock No. 20954P, 0692 Rev. F, 06/12

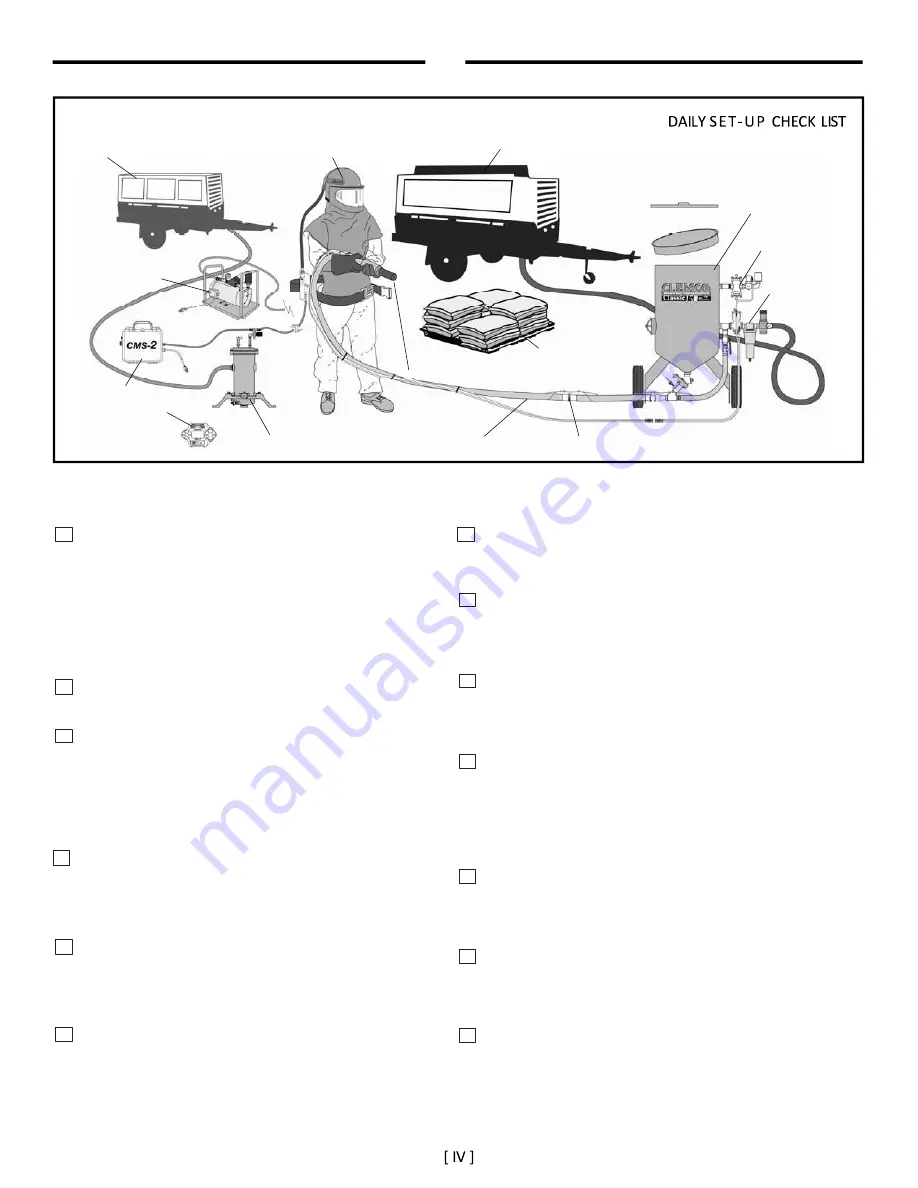

1. Air Compressor

7. Air Line

Moisture

Separator

5. CPF Air Filter

6. ASME Code

Blast Machine

8. Remote

Controls

9. Blast Hose

10. Hose Couplings and Safety Cables

11. Appropriately Sized Nozzle

12. Abrasive

4. External or

Helmet Mounted

Carbon Monoxide

Monitor /Alarm

2. Breathing Air Compressor for

High Pressure Respirators

3. NIOSH Approved

Supplied-Air Respirator

or Ambient Air Pump for

Low Pressure Respirators