Accessories

7-2

750-297

Profire E/LNE Series Manual

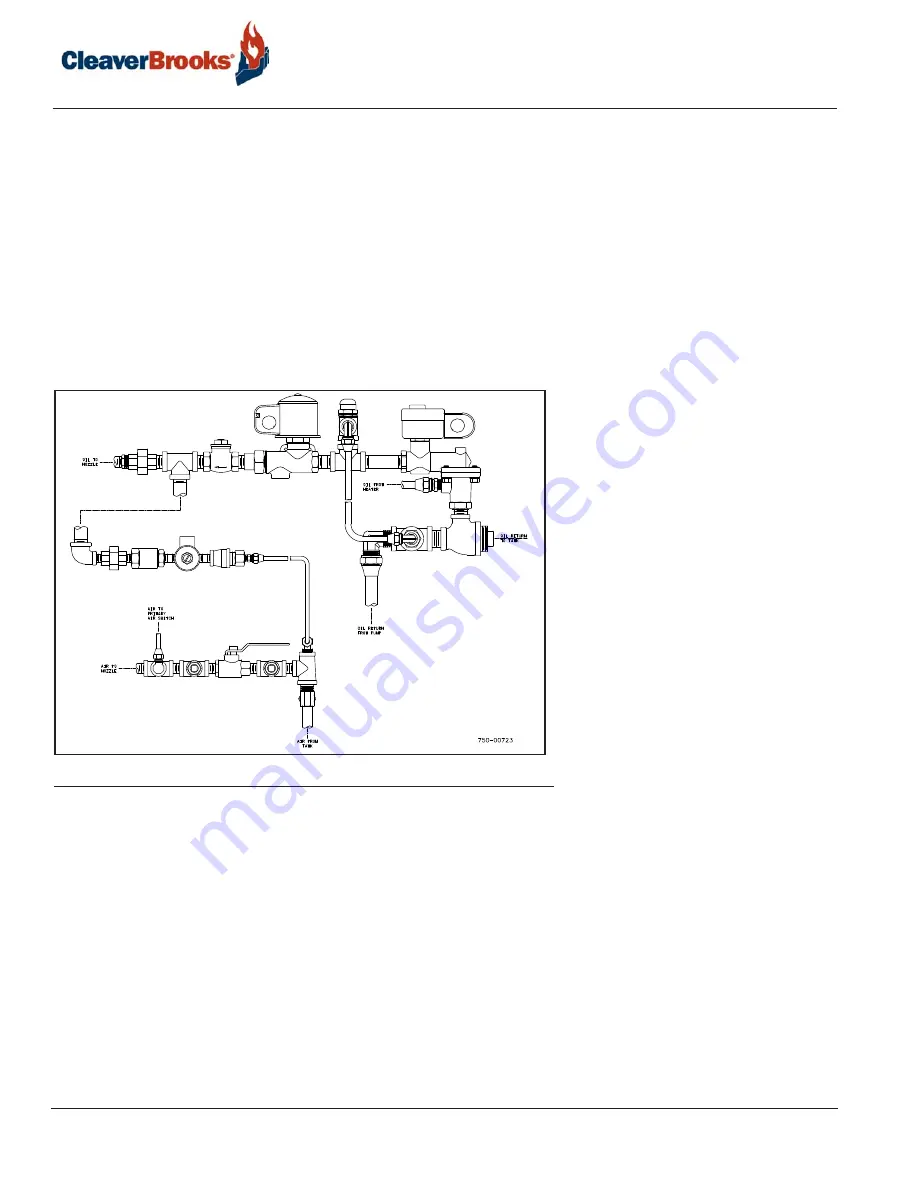

The steam atomizing line is shipped loose and must be piped and wired to the burner as shown in the diagram below.

Refer to the wiring diagram for the electrical connection. The air compressor is used for cold oil startup. Start the boiler

with the air atomizing system first. Once the boiler reaches operating pressure, shut down the unit, close the shut-off

valve on the air line and open the one on the steam line. Set the Air / Steam switch to the Steam position. Restart the

unit with the steam atomizing system. You must have a minimum of 70 PSI at the inlet of the steam regulator. Open the

needle valve to its maximum. Adjust your steam pressure with the regulator to have 30 PSI on the discharge side of the

regulator. While the unit is purging, screw in and adjust the needle valve to have 10-15 PSI in low fire. Install a

pressure gauge to monitor the pressure. One or two regulator is supplied depending on the boiler operating steam

pressure. Follow the instructions in the Chapter 4, Adjustments, to set up the burner. Fine tune the steam atomizing

with the needle valve.

7.3 — Air Purge System (optional)

The nozzle line air purge option is used to

purge the oil out of the nozzle line using

the air compressor on a burner shutdown.

The air purge line is mounted and piped on

the burner. The air line from the

compressor to the air purge line is by

others.

FIGURE 7-2.

Air Purge System

7.4 — Plant Air System

The E series burners are able to operate with a plant air system instead of the standard IC compressor. In such cases, the

burner is supplied with an atomizing air regulating line.

Adjust the air pressure with the regulator and fine tune with the needle valve to have 10-15 psi on low fire. Refer to

Chapter 4 to setup the burner.