750-297

Profire E/LNE Series Manual

5-3

Maintenance

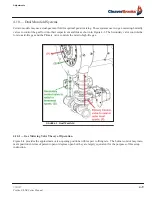

5.5 — Pilot and Ignition Electrode

The ignition transformer requires little attention other than making sure the

ignition wire is firmly attached to the transformer and the electrode. Be

sure the wire insulation is in good condition and not grounded. Failure to

keep the ignition electrode clean and properly set can cause faulty

operation. Refer to Figure 5-3 for electrode gap setting and position. The

pilot assembly is supported by a socket in the diffuser and gas inlet tube.

No adjustment is required except proper positioning of the electrode wire.

FIGURE 5-2.

Pilot Electrode Gap

5.6 — Flame Scanner

The scanner must be clean. Even a small amount of contamination will reduce the flame signal. Wipe the scanner lens

with a clean soft cloth.

5.7 — Oil Nozzle

Successful burner operation requires use of the proper style nozzle tip and keeping the orifice clean. Standard nozzle

tips furnished on the burners are of a special emulsifying type which delivers a spray of extreme fineness and at an

angle which insures proper mixing with the air stream. Unsatisfactory performance and loss of efficiency can result

from the use of nonstandard nozzle tips. If the burner flame becomes stringy or lazy, it is possible that the nozzle spring

is not properly in place or the nozzle is clogged. This problem is usually indicated by an abnormally high reading on the

atomizing air pressure gauge on the air-oil tank. To remove the nozzle:

1.

Disconnect the oil and air tubes to the nozzle assembly.

2.

Loosen the three 1/4” screws holding the nozzle spider bracket to the diffuser.

3.

Withdraw the nozzle and bracket assembly.

To clean the nozzle tip and swirler:

1.

Unscrew the tip from the nozzle body. Use care not to distort the tube.

2.

Hold the nozzle body in a vise or use two wrenches, one on the body and one on the tip.

3.

Disassemble the nozzle tip.

4.

Carefully clean all parts in solvent and reassemble the nozzle.

1/8"