750-297

Profire E/LNE Series Manual

4-7

Adjustments

actuators for fuel, air, and FGR (if so equipped) will be coordinated to provide optimum combustion throughout the

firing range.

4.9 — Firing Rate Controls

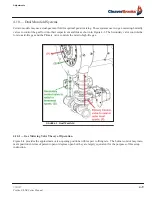

Firing rate adjustments are made at the modulating motor linkages to the combustion air inlet damper, air-oil metering

pump, and main gas butterfly valve. Settings are determined by the operating length of the levers and the angular

position on the shafts. Increasing the lever lengths on damper, pump or valve decreases the flow rate. Driving and

driven levers are approximately parallel, but the angles can be adjusted to vary the rate of change. The most rapid rod

travel occurs when the lever is perpendicular to the rod. The closer the rod comes to being parallel with the lever, the

slower the rod moves. ALWAYS allow the burner to return to low fire position before adjusting high or intermediate

settings. DO NOT alter low fire settings.

Normally, the air control damper will be approximately 1" open in low fire position. Excessive opening in low fire can

cause pilot ignition problems. Air to the pilot is supplied under pressure to compensate for variations in furnace

pressure, but the damper must be in low fire position for reliable ignition.

Keep fingers away from the air intake below the damper. The damper is actuated with sufficient force to cause severe injury.

!

Warning