10

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

• Check the hydraulic connections for leaks. Replace or properly repair any

damaged or leaking hydraulic components before using. In the event of

leaking seals, oil can be topped up via the plug on the end of the pump. Oil

should be level with the bottom of the hole. If necessary top up with CLARKE

hydraulic oil, Part No. 3050830.

This task is carried out with the ram fully

retracted.

• If any rust is apparent it must be removed completely and the paint restored.

DE-COMMISSIONING PRODUCT

Should the product become completely unserviceable and require disposal,

draw off the oil into an approved container and dispose of the product and

the oil according to local regulations.

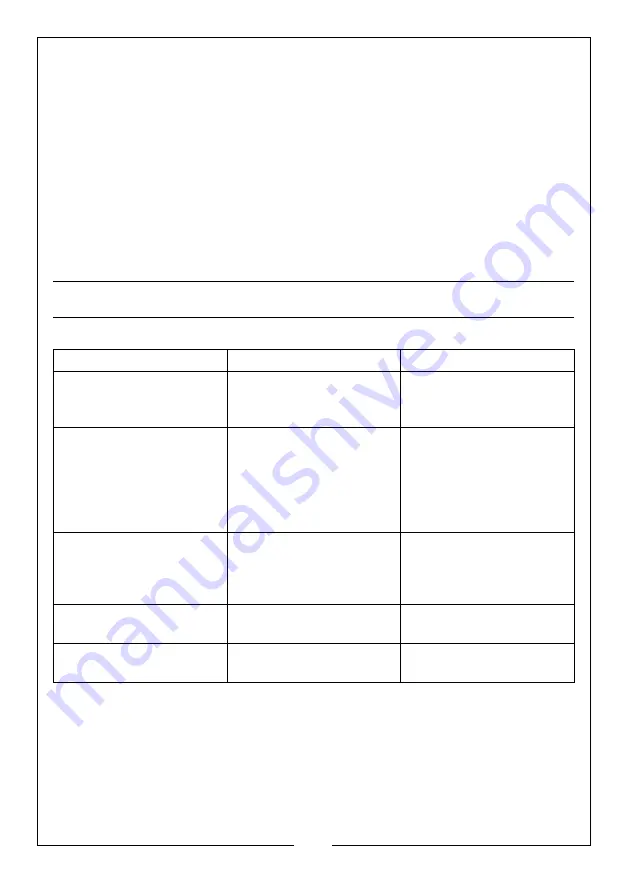

TROUBLESHOOTING

Problem

Probable Cause

Remedy

Pump unit will not work

Dirt on valve seat/warn

seals

Bleed pump unit or have

unit overhauled with new

seals

Pump will not produce

pressure

Pump feels hesitant

under load

Pump will not lower com-

pletely

Air-lock

Open the release valve

and remove the oil filler

plug. Pump the handle a

couple of full strokes and

close the release valve.

Replace the filler plug.

Pump will not deliver

pressure

Reservoir could be over-

filled or have low oil level.

Check oil level by

removing the filler plug

and topping up to the

correct level.

Pump feels hesitant

under load

Pump cup seal could be

worn out.

Have the cup seal

replaced.

Pump will not lower

completely

Air-lock

Release air by removing

the filler plug

Summary of Contents for STRONG-ARM CSA12F

Page 16: ......