Fig. 6

9

B.

PERIODICALLY

1. After the first 5 hours of running the compressor, check the cylinder head

bolts and motor housing screws and re-tighten if any have worked loose.

2. Every 50 hours (more frequently if used in a dusty environment), clean the air

intake filter, by carefully removing the single screw securing the plastic cover

and withdrawing the sponge element from inside.

Clean the sponge and the inner housing. If necessary, the sponge filter may

be gently washed in warm soapy water, rinsed and allowed to dry thoroughly

before refitting. Ensure that the outer filter cover is then screwed back into its

original position.

If any part of the filter is damaged then you should obtain a replacement.

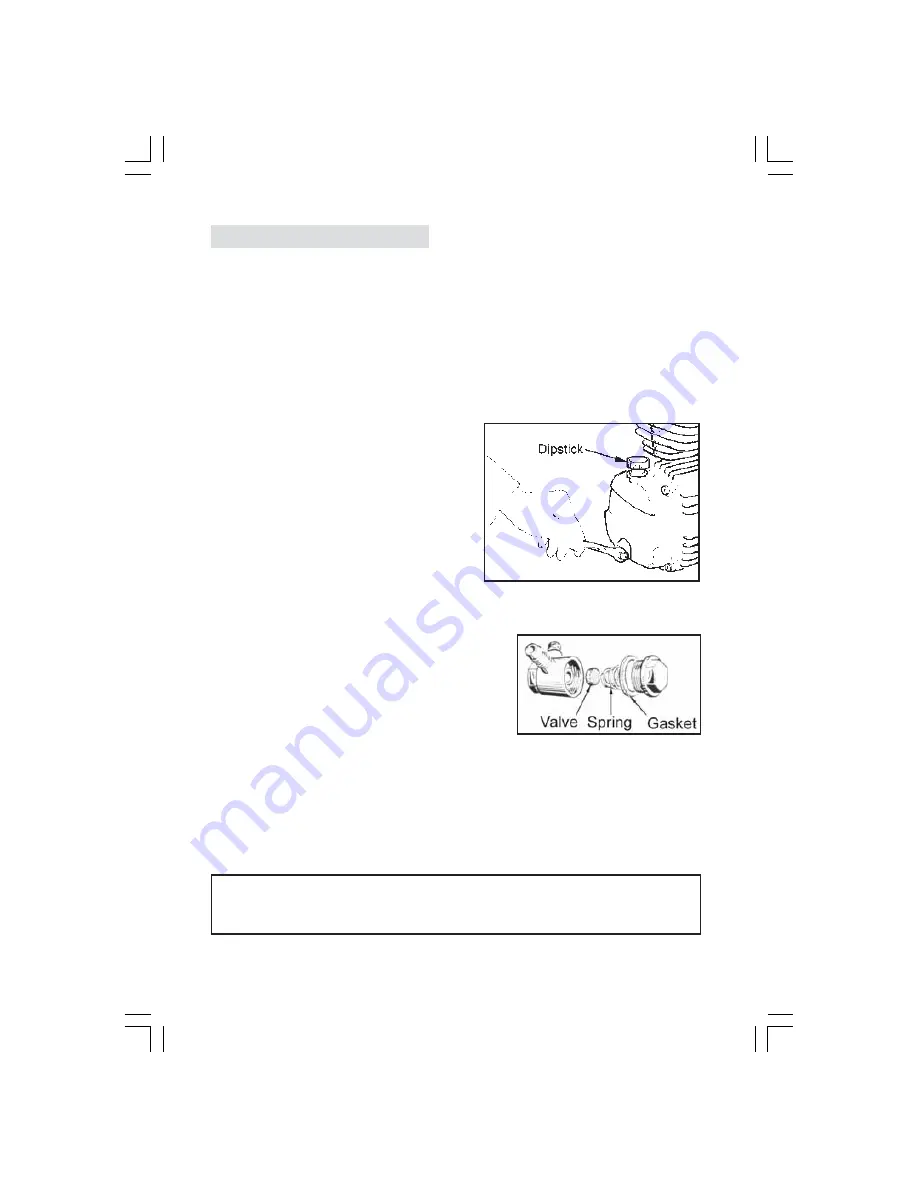

3. After the first 100 hours use, replace the

oil completely using Clarke SAE 40

compressor oil. Thereafter, replace the

oil completely after every 500 hours

of operation or every 6 months.

To empty the oil from the machine,

remove the drain plug from the

crankcase cover (see fig. 6).

4. Every 500 hours of operation or every

6 months

•

clean all the external parts of the

compressor.

(This cleaning makes the cooling

process more efficient and prolongs

the life of the machine).

•

Check and clean the inlet and outlet

valves

•

Examine the non-return valve and

replace the gasket if necessary (fig.7)

5. In the event of an air leak follow the procedure below:

•

Load compressor to maximum pressure

•

Unplug the compressor

•

With a brush and soapy water wet all ‘screwed’ air connections

•

Any leaks will show through the formation of air bubbles.

WARNING

NEVER UNSCREW A CONNECTION WHILST THE AIR RECEIVER IS UNDER PRESSURE.

ALWAYS MAKE CERTAIN THAT THE TANK HAS FIRST BEEN EMPTIED.

Fig. 7

Parts List item No. 59