9

3. With assistance if required, rest the upper drum so that it sits on the rim of

the lower drum. Rotate it so that the screws enter the fixing holes from

below. Look to see that the holes for the upper mountings of the mixing

blades also line up with those in the upper drum.

4. When all fixings are correctly lined up, use the screws, nuts and flat

washers to gently pull the upper and lower drum halves together, gripping

the seal between them. Look inside the drum to check that the seal is

sitting correctly in position.

NOTE: It is desirable practice for the screws to be fitted from above,

therefore, remove them one at a time and re-fit the correct way,

adding a spring washer at each position.

5. Finally, tighten all the fastenings progressively.

6. Secure the mixing blades to the upper drum by inserting the dome

headed coachbolt, through the hole in the drum from the outside,

ensuring the square portion of the bolt seats in the square hole in the

drum. The leather washer should bear against the drum.

7. Secure the mixing blade on the inside using a flat washer, spring washer

and nut.

8. Finally, ensure top and bottom mixing blade mountings are tight.

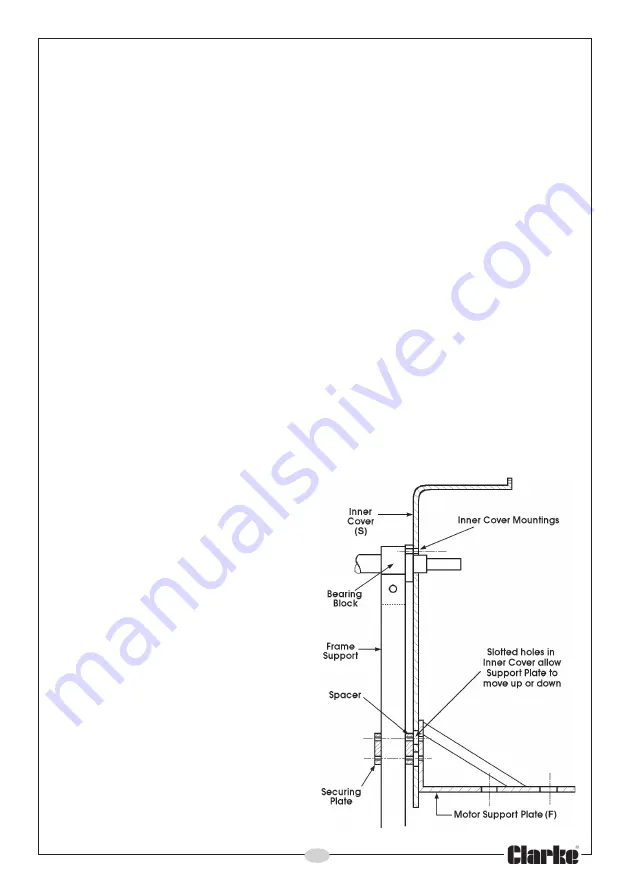

THE MOTOR COVER, MOTOR SUPPORT & DRIVE PULLEY

Note: To restrain it in transit, the

motor will be found bolted

to the inner cover with

suitable packing materials.

Remove the bolts which are

used for this.

1. Bolt the inner motor cover (S) to

the bearing block using two M8 x

25mm bolts with flat washers at

the bolt heads, from within the

inner cover, and spring washers

with nuts to the rear of the

bearing block. Leave the nuts

loose at this stage.

2. Attach the motor support plate

(F), as shown in Fig. 6, by inserting

four M6 x 65mm bolts, through

the holes in the support plate (F),

the slotted holes in the inner

cover (S), and the spacer, which

is inserted between the back of

the inner cover, and the frame

(see fig 6).

Fig. 6

Summary of Contents for CCM125C

Page 13: ...13 COMPONENT PARTS DIAGRAM...

Page 15: ...15 DECLARATION OF CONFORMITY...

Page 16: ......