27

Continued On Next Page

☛

☛

☛

☛

☛

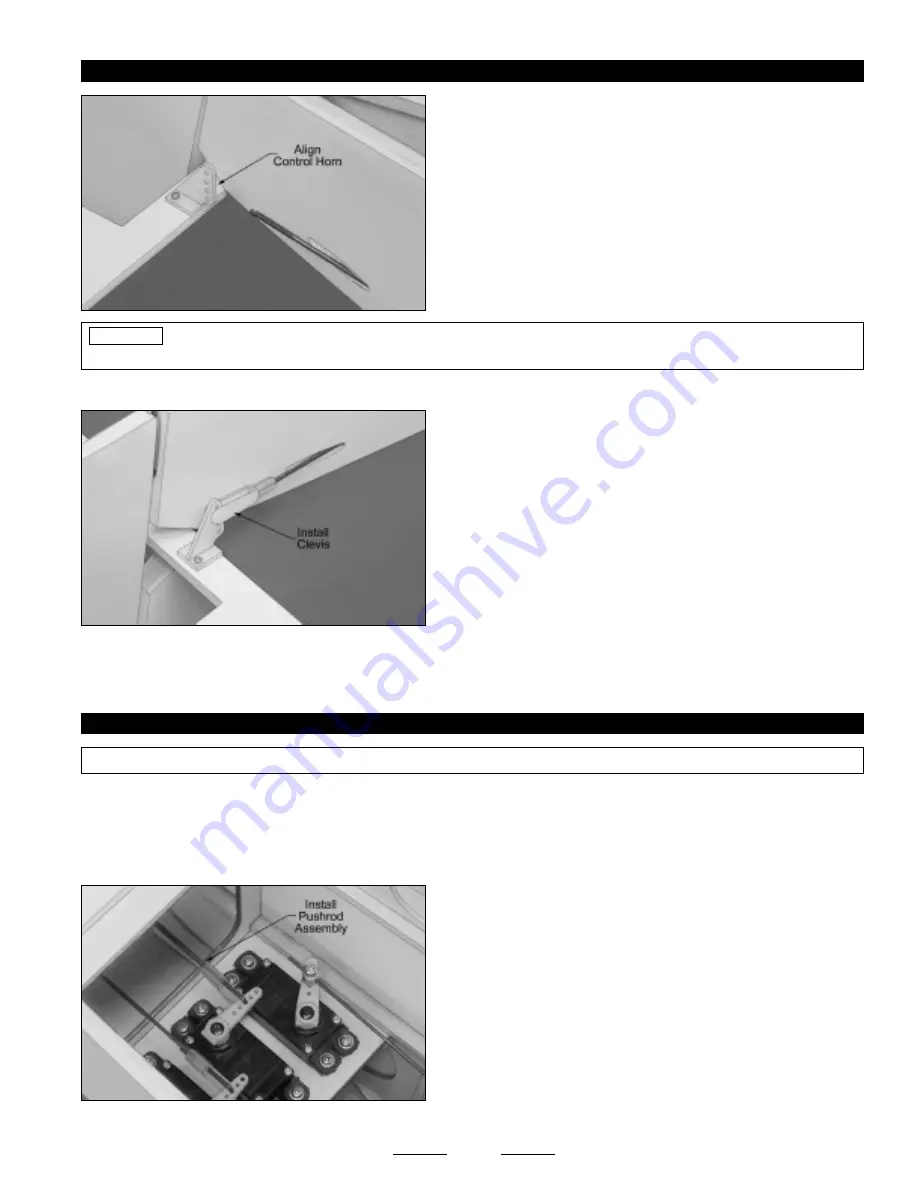

STEP 3: INSTALLING THE ELEVATOR CONTROL HORN AND CLEVIS

❑

Position one nylon control horn onto the bottom left side of the

elevator. When aligned properly, the centerline of the control horn should

be about 5/16" out from the side of the fuselage (at the hinge line) and

the clevis attachment holes should be lined up over the hinge line. The

base of the control horn should be parallel to the hinge line, too.

❑

When satisfied with the alignment, mark and drill 5/64" diameter

pilot holes through the elevator for the control horn mounting screws.

Before installing the control horn in the next procedure, drip several drops of thin C/A into the pilot holes and allow

the C/A to fully cure. The C/A will harden the surrounding wood, making the mounting area stronger.

❑

Install the control horn and backplate, using two M2 x 12mm machine screws, being careful not to overtighten them.

PRO TIP

❑

Connect your radio system and plug the rudder servo (middle servo)

into the receiver. Double-check that the rudder trim lever on your

transmitter is centered.

❑

Carefully slide the threaded end of the pushrod wire into the

preinstalled pushrod housing on the right side of the fuselage.

❑

Install the servo horn onto your servo, making sure that it's centered

and pointing toward the throttle servo.

❑

Use a couple of pieces of masking tape, taped between the elevator

and the stabilizer, to hold the elevator centered.

❑

Thread one nylon clevis onto the pushrod wire and snap the clevis

into the

third hole

out from the base of the control horn.

☞

To make it easier to install the clevis, remove the servo arm from

your servo and pull the pushrod wire back far enough to give yourself

enough room to thread the clevis on. Hold the pushrod wire with a pair

of pliers to prevent it from turning while installing the clevis.

❑

Remove the masking tape from the elevator and double-check that the servo arm and the elevator are still centered. If the

elevator is not centered, adjust the clevis until it is. Move the elevator up and down several times to ensure that the pushrod

assembly does not bind. It should operate smoothly.

STEP 4: INSTALLING THE RUDDER PUSHROD

✦

✦

✦

✦

✦

IMPORTANT

✦

✦

✦

✦

✦

The rudder pushrod is installed using the same techniques that you used to install the elevator pushrod.

❑

Remove all but one arm from a "4-point" servo horn and install the 90º bend in the 17-7/8" long threaded pushrod wire into the

hole that is 9/16" out from the center of the remaining servo arm, using the nylon snap-keeper provided.

❑

Using a modeling knife, cut away and remove the covering material from over the rudder pushrod exit hole in the right side of the

fuselage. The hole is located 2-3/4" in front of the rudder hinge line and 1-1/4" below the horizontal stabilizer.

❑

Install the servo horn retaining screw to secure the servo horn to the servo.