2-2

2.1 Control Panel

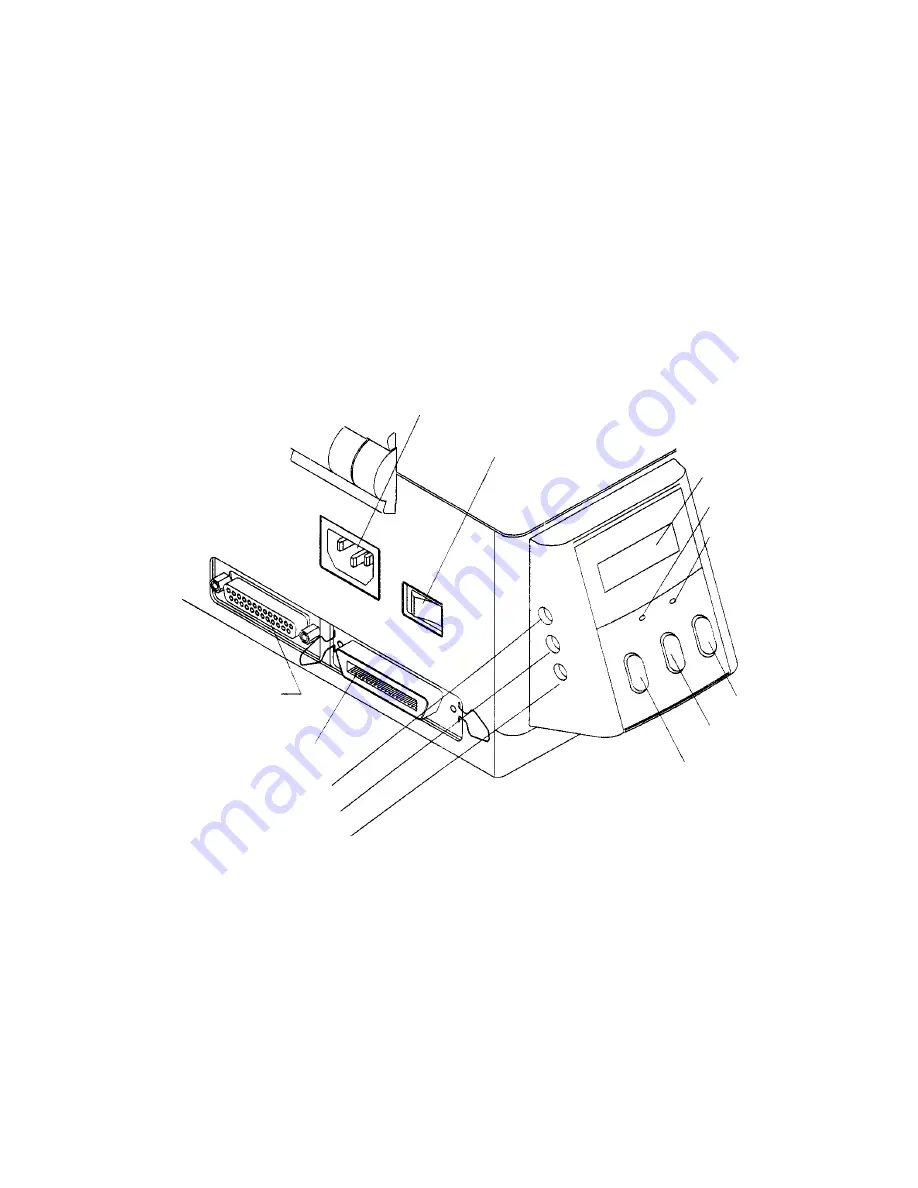

The control panel, on the front of the printer, consists of three control keys

(Pause, Feed and Stop), two LED indicator lights (Power, Error), and a LCD

message screen. On the left side of the control panel there are three

adjustment controls (paper gap, black line and LCD contrast).

Exterior view of the control panel

Serial interface connector

Parallel interface connector

Paper gap adjustment control

Black line adjustment control

LCD contrast adjustment control

Stop key

Feed key

Pause key

LCD

LED power indicator

LED error indicator

Power switch

Power inlet

Summary of Contents for CLP-6401

Page 1: ...CLP 6401 User s Manual C ITOU...

Page 13: ...xii...

Page 36: ...3 7 Roll paper Roll paper Notch for alignment Reference plane...

Page 40: ...3 11 Heating element b...

Page 57: ...4 11...

Page 59: ...4 13...

Page 63: ...5 4...

Page 82: ...6 19...