Installing an Interface Module

Procedure

Step 1

Before inserting an interface module, make sure that the chassis is grounded.

Step 2

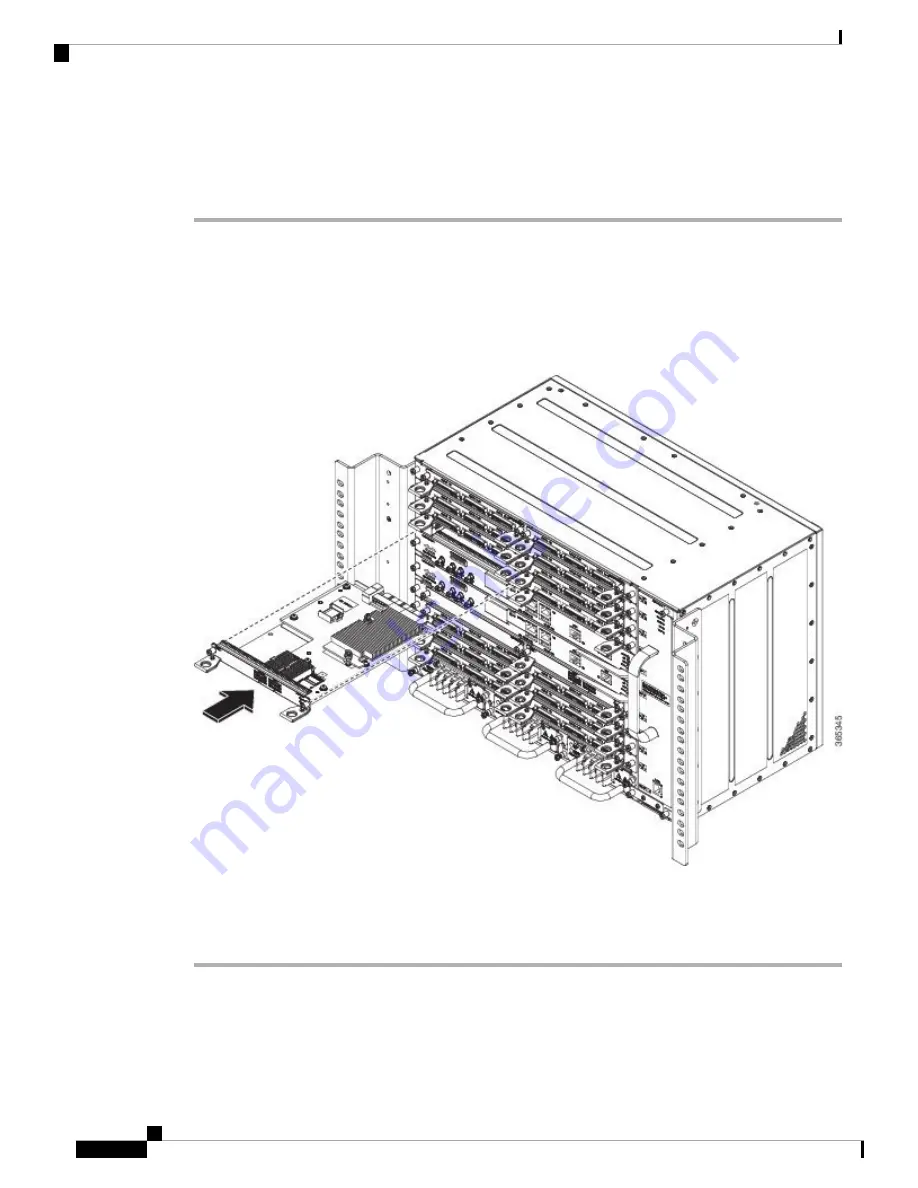

To insert the interface module, carefully align the edges of the interface module between the upper and lower

edges of the router slot.

Step 3

Carefully slide the interface module into the router slot until the interface module makes contact with the

backplane. The following figure shows how to install the interface module.

Figure 23: Inserting an Interface Module

Step 4

Tighten the locking thumbscrews on both sides of the interface module. The recommended maximum torque

is 5.5 in.-lb (.62 N-m).

Step 5

Connect all the cables to each interface module.

Installing the Cisco NCS 4216

30

Installing the Cisco NCS 4216

Installing an Interface Module