Installing the Fan Tray from the Front Panel of the Chassis

Before you begin

• Read

Guidelines for Removing and Installing a Fan Tray, on page 63

• Enable the service mode on the chassis, if you are performing this task in a system that is powered on.

• Ensure that you have the following tools and accessories available:

• Phillips-head screwdriver

• Anti-static mat

Procedure

Step 1

Hold the fan tray assembly with the fans facing to the right.

Step 2

Place the fan tray into the fan tray slot so it rests on the chassis, and then lift the fan tray up slightly, aligning

the top and bottom guides.

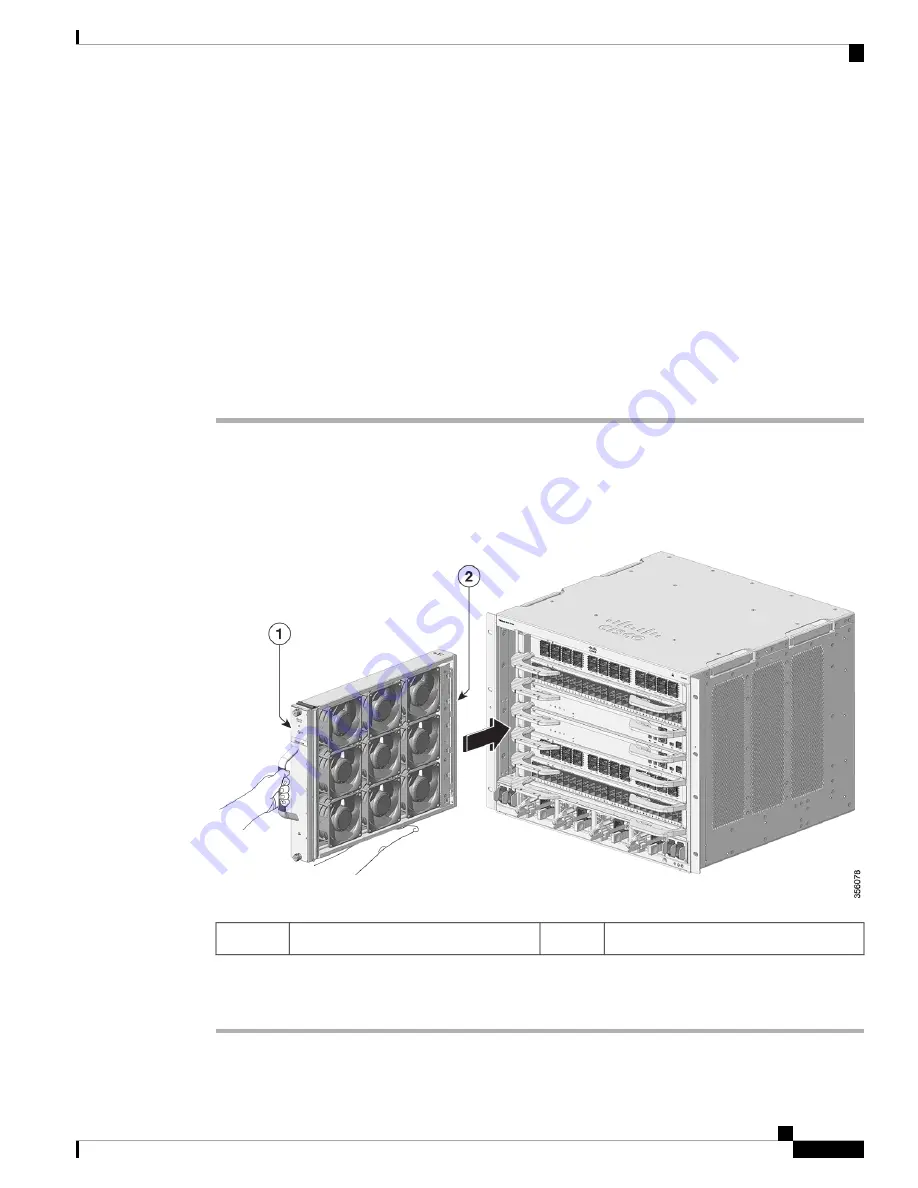

Figure 37: Inserting the Fan Tray from the Front of the Chassis

Fan tray without the connector

2

Front side of the fan tray

1

Step 3

Slide the fan tray into the chassis until the two captive installation screws make contact with the chassis.

Step 4

Tighten the two captive installation screws on the front, to secure the fan tray assembly in the chassis.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

71

Installing the Fan Tray

Installing the Fan Tray from the Front Panel of the Chassis