prevent reverse rotation of the impeller and motor.

Electrical Requirements

·

Install all equipment in accordance with the National Electrical Code and all applicable local

codes and ordinances

·

A means for disconnection must be incorporated in the fixed wiring in accordance with the

wiring rules.

Note:

ALWAYS reinstall the lid onto the field wiring compartment when leaving the pump

unsupervised during servicing. This will prevent foreign matter (i.e. rainwater, dust, etc.) from

accumulating in the field wiring compartment.

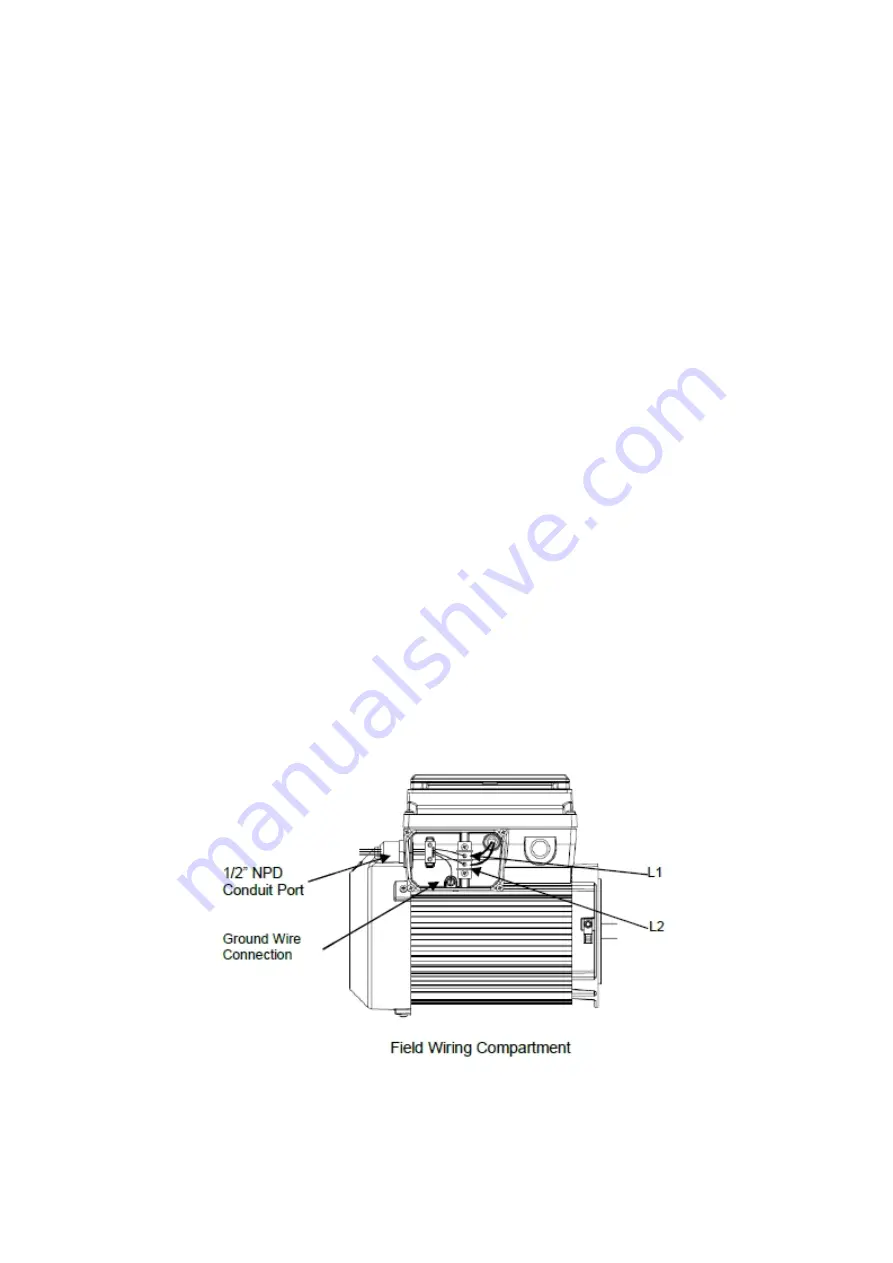

Wiring

1. Be sure all electrical breakers and switches are turned off before wiring motor.

STORED CHARGE

- Wait at least sixty (60) Seconds before servicing.

2. Be sure that the supply voltage meets the requirements listed on the motor nameplate. If

these requirements are not met, permanent motor damage may occur.

3. For wiring sizes and general guidelines for proper electrical installation, please follow the

specifications

defined in the National Electric Code and any local codes as required.

4. Use strain relief and be sure all electrical connections are clean and tight.

5. Cut the wires to the appropriate length so they do not overlap or touch when connected.

6. Reinstall the keypad cover after wiring the pump plugging the cover back into the drive

wiring connection and re-seating the keypad cover in the desired orientation with the four (4)

corner screws.

Note:

Ensure that the keypad cable is not pinched between the drive and keypad cover during

re-seating.

5