- 22 -

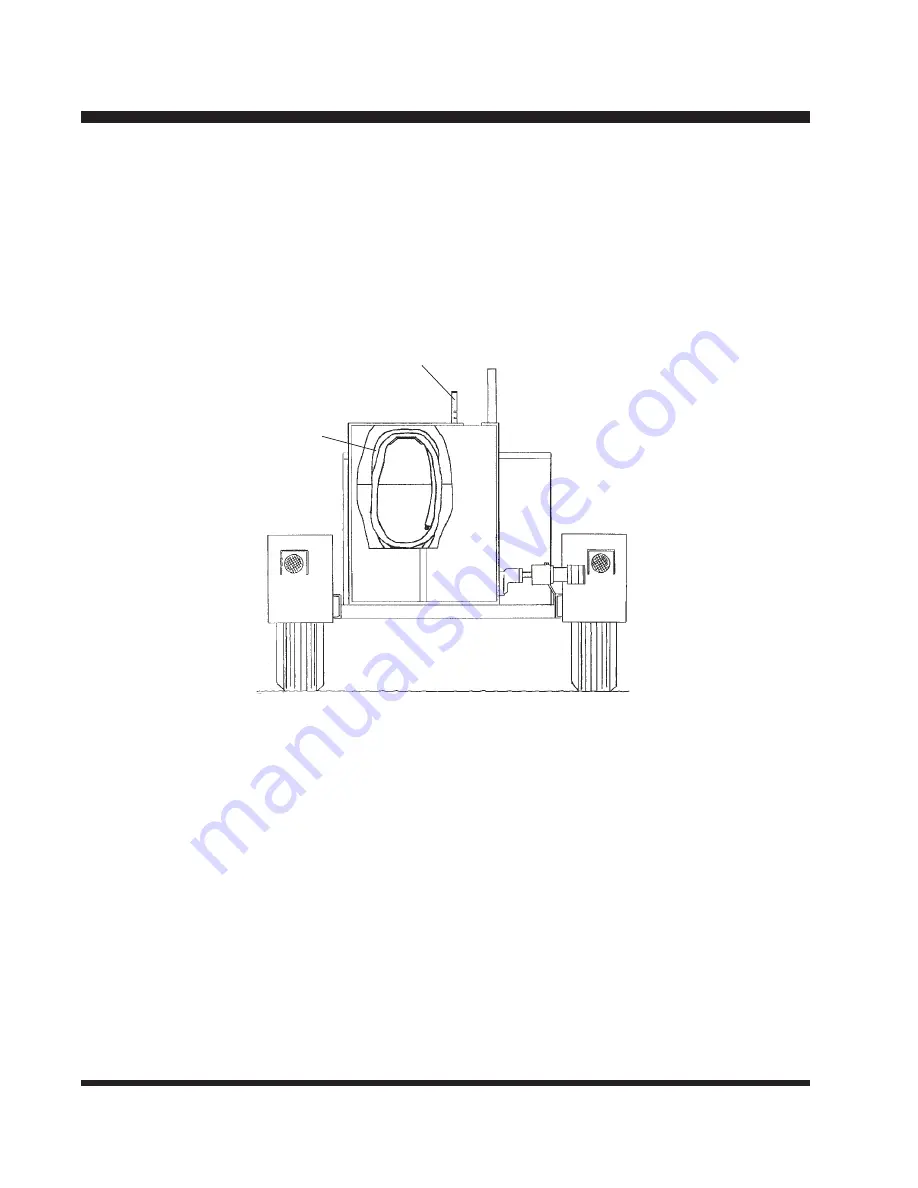

Unplugging a Clogged Hose (Non-Heated Hose Models)

COILED HOSE

THERMAL REGULATING GATE

Regardless of how you store your hose, the residue tends to settle at the bottom of the coils

overnight. Each day when the unit is started, the hose must be coiled up and placed in the

cabinet during the preheating process, as shown in the picture below. Unless the hose was

cleaned with compressed air, you will probably have enough material remaining in the hose to

require this procedure.

NOTE: Once the Melter is up to operating temperature, the burner typically does not

cycle often enough to get the cabinet to the required temperature to unplug

the hose.

On cold and windy days, it is very important to maintain material flow through the hose at all

times. This requires keeping the material up to temperature and returning the wand to the

access port anytime the wand will be shut off for more than 30 seconds to a minute. If the hose

plugs during sealing operations, one of the following procedures should be followed:

1)

Immediately

remove the sealing tip (if you are using one) and insert the wand into the

access port. With the sealing hose valve and the wand valve both wide open, turn the

pressure valve clockwise to increase the pressure supplied to the hose. Do this until

the engine almost stalls. If this does not work, proceed to another method.

NOTE: Immediately coil the hose inside the cabinet.