OPERATING MANUAL

MIG (GMAW) WELDING

5-16

Manual 0-5586

Press the Voltage Control Knob, and the Heat Control value or pre-set volts will be displayed in the right

display in turn.

Note: when switching from pre-set volts to Heat Control value display, the Heat Control value will remain

for 5s and then return to pre-set volts if there is no more adjustment; if you adjust the Heat Control value,

it will keep displaying the Heat Control value.

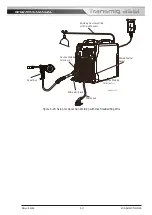

5.14 Setup for Manual MIG (GMAW) Welding with Gas Shielded MIG Wire

A. Fit the MIG Torch to the Power Source. (Refer to Section 5.06 the Tweco Professional Fusion MIG Torch).

B. Connect the Mig Torch polarity lead to the positive welding terminal (+). If in doubt, consult the electrode

wire manufacturer. Welding current flows from the power source via Dinse terminals. It is essential, however,

that the male plug is inserted and turned securely to achieve a sound electrical connection.

C. Switch the Power Source On/Off switch located on the rear of the Power Source to the On position and

ensure the Power indicator on the Front Panel is illuminated. Set the MIG Torch trigger switch operation

either 2T or 4T mode. Refer to Section 4.02.15.

D. Select MIG mode with the process selection control (refer to Section 4.02.12 for further information).

E. Fit the correct Feed Roll for the Gas Shielded MIG wire being used. Refer to Section 2.11 Options and

Accessories for Feed Roll types and Part Numbers

F. Place the MIG wire spool onto the spool holder. Refer to Section 5.07 for 300mm diameter spools or 5.08

for 200mm diameter spools.

G. Feed wire through the wire drive mechanism. Refer to Section 5.09.

H. Connect the work lead to the negative welding terminal (-). If in doubt, consult the electrode wire

manufacturer. Welding current flows from the power source via Dinse terminals. It is essential, however,

that the male plug is inserted and turned securely to achieve a sound electrical connection.

I. Set Internal Switch in the wirefeeder compartment to <1> Local / 4RX / Spool Gun position. Refer to Section

4.02.26.

J. As a guide for the welding parameter settings for the welding job refer to the Weld Guide located on the

inside of the wirefeed compartment door. Power Source settings are adjusted using the front panel controls.

Refer to Section 4.02.

!!

WARNING

Before connecting the work clamp to the work make sure the mains power supply is switched off.

!!

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug being fused in the terminal.

Remove any packaging material prior to use. Do not block the air vents at the front or rear of the Welding Power Source.

Summary of Contents for Transmig 355i

Page 8: ...This Page Intentionally Blank ...

Page 14: ...OPERATING MANUAL GENERAL INFORMATION 1 6 Manual 0 5586 This Page Intentionally Blank ...

Page 24: ...OPERATING MANUAL INTRODUCTION 2 10 Manual 0 5586 This Page Intentionally Blank ...

Page 28: ...OPERATING MANUAL INSTALLATION 3 4 Manual 0 5586 This Page Intentionally Blank ...

Page 84: ...OPERATING MANUAL TIG GTAW WELDING 6 10 Manual 0 5586 This Page Intentionally Blank ...

Page 110: ...OPERATING MANUAL KEY SPARE PARTS 9 4 Manual 0 5586 This page intentionally blank ...

Page 112: ...OPERATING MANUAL APPENDIX A 2 Manual 0 5550 This Page Intentionally Blank ...

Page 115: ...OPERATING MANUAL Transmig 220i This Page Intentionally Blank ...