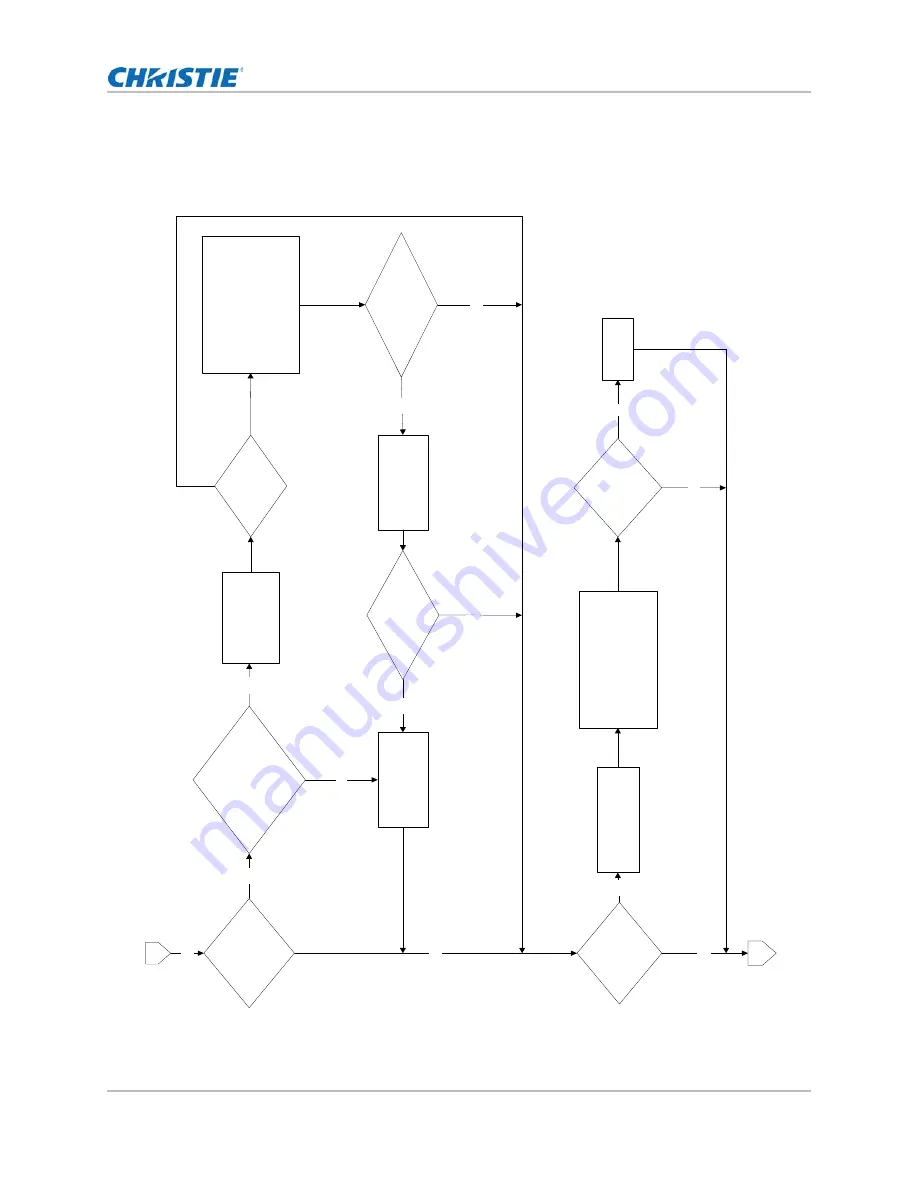

Troubleshooting

H Series Service Manual

40

020-000802-03 Rev. 1 (12-2016)

Verify image performance

Is there

a ve

rtical

(or

hori

zontal) line in

the imag

e?

Do

es

the l

ine

remain in the

same

location when

switching between

test

patterns?

Check the

connection between

the

DMD bo

ard

and

the mai

n board.

Does the

line still

appe

ar in

the

image?

Check the

connection between

the

DMD mo

dule

and

light

engine modul

e. Ensure there is

no dust on the socket and

LVDS

bu

s to DM

D (gold fin

ger

)

and thi

s need to be done in a

clean room

Is

the

re

n

o

is

e in

the imag

e?

Ensure that the signal

cable

and

signal source

are wo

rk

ing

Adjust the pix

el phase by

selecting

:

1. Size

& Position

2. Pi

xel phase to

adjust phase,

in the

Menu.

Has the Image

noise been

resolved?

Re

place the

mai

n bo

ard

Yes

No

No

Yes

Yes

No

Yes

1-

3

Yes

ŏŰ

Does

the line still

appear in the

image

?

Yes

Re

place the DMD

board

Does the

line still

appe

ar in

the i

m

age

?

Yes

No

No

Yes

Ś

ŦŴ

No

Re

place the main

board

1-

4