WM210-220-230-240S/SI

Installation Instructions

6

SITE REQUIREMENTS (WM2XXS

I

and WM2XXS Models) - Steel Stud Structure

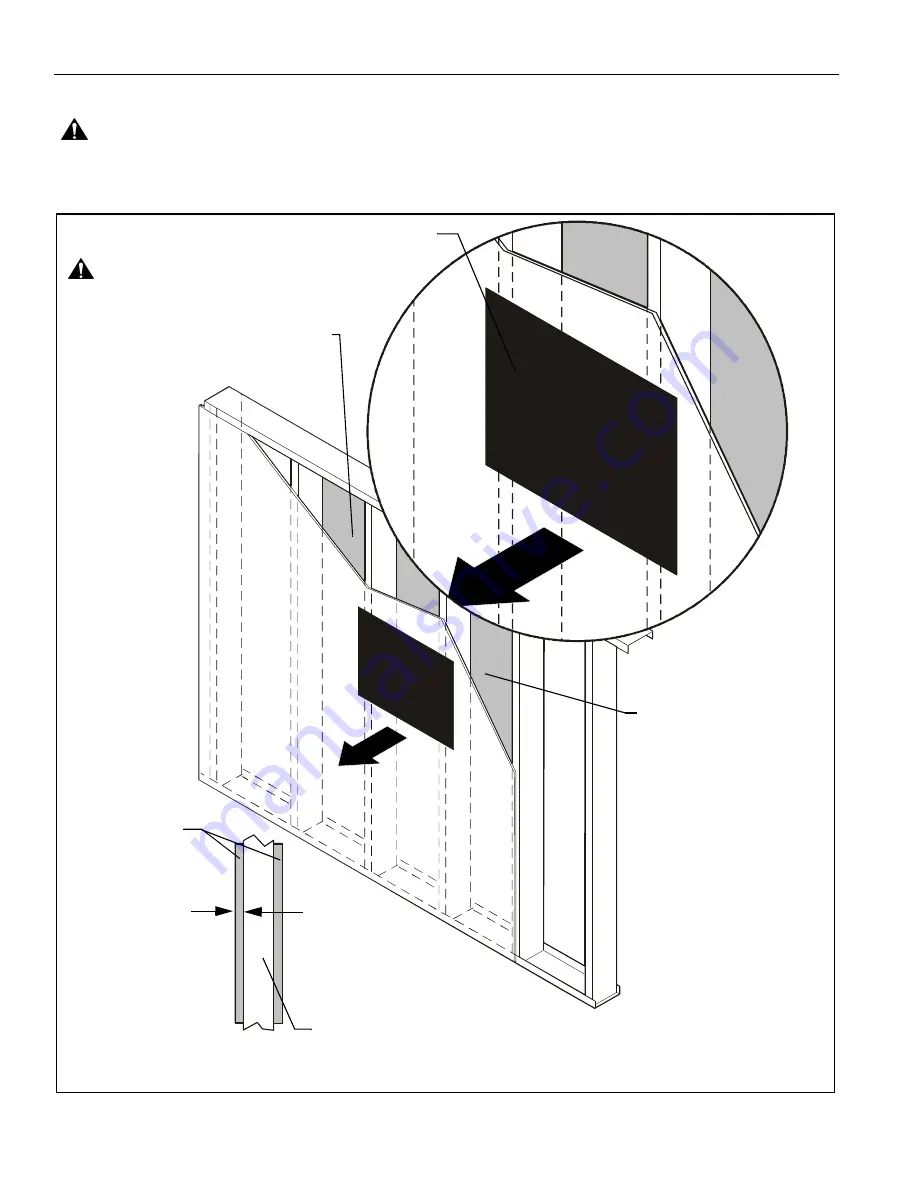

WARNING:

IMPROPER INSTALLATION CAN LEAD TO EQUIPMENT FALLING CAUSING SERIOUS PERSONAL INJURY

OR DAMAGE TO EQUIPMENT! The figure below identifies the minimum requirements for installation of display mounts onto a

steel stud structure. If the structure or its components do not meet these requirements contact the mount manufacturer for specific

instructions before attempting installation. It should also be noted that no other equipment should be mounted to the same stud.

(See Figure 1)

Figure 1

(Must be centered on stud)

Drywall

**1/2" minimum

Drywall Thickness

Display Mount Installation Location

FRONT

(Both Sides of Stud)

There must be a minimum of

1-7/8" (48mm) clearance

inside wall

16" or 24" (on center) Studs

If back side of wall is unfinished, drywall must be installed

to a minimum of one stud left and right of the stud(s)

being used to install the mount. Drywall must be

secured to studs with screws 12" on center

Steel Stud (2 x 4 / 25ga minimum)

Stud type and structural strength must conform to the North American

Specification for the Design of Cold-Formed Steel Structural Members.

**See hazard statement

on page 2!

[362, 125 18, C-Shape, S - Stud Section]