To Attach The Side Handle:

1.

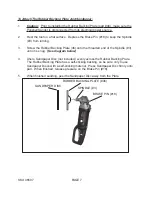

NOTE: The Side Handle (part #20) may be attached either on the right, left, or

top side of the Polisher/Sander. (See Figure C, and Assy. Diagram.)

2.

To attach the Side Handle (part #20), remove the Rubber Plunge (part #19) from

either the right, left, or top side of the Polisher/Sander in order to expose the

threaded mounting hole. (See Figure C, and Assy. Diagram.)

3.

Firmly

hand tighten the threaded portion of the Side Handle (part #20) into the

desired mounting hole of the Polisher/Sander. (See Figure C, and Assy. Dia-

gram.)

MOUNTING

HOLE

BRAKE PIN (#18)

MOUNTING HOLE

SIDE HANDLE (#20)

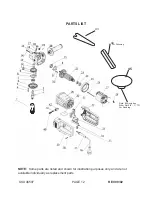

WOOL COVER (#45)

BRUSH CAP (#40)

CARBON BRUSH (#41)

BRUSH HOLDER (#42)

VARIABLE SWITCH (#31)

BACK HANDLE (#39)

POWER CORD (#36)

MOUNTING HOLE

BRUSH CAP (#40)

CARBON BRUSH (#41)

BRUSH HOLDER (#42)

SWITCH

LOCK

FIGURE C

OPERATING INSTRUCTIONS

NOTE: For additional references to the parts listed below, refer to the Assembly

Diagram on page 12 of this manual.

SKU 46507

PAGE 8