SKU 46507

PAGE 10

parts and any other condition that may affect its safe operation. If abnormal

noise or vibration occurs, turn off the Polisher/Sander immediately and have the

problem corrected before further use. Do not use damaged equipment.

3.

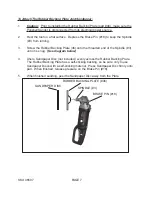

The Polisher/Sander features

two Carbon Brushes (part #41) which, periodically,

should be examined for wear. The Carbon Brushes are located on each side of

the Plastic Housing (part #29). To inspect or replace the Carbon Brushes, use a

small standard screwdriver to remove the Brush Cap (part #40). Examine the

concave surface of the Carbon Brushes. The surface should be smooth and

clean. If there are large scratch marks in the Brushes, or parts of the Brushes

have broken off, replace

both Brushes immediately with approved replacement

Brushes from Harbor Freight Tools. To reinstall the Brushes, insert them into the

two Brush Holders (part #42). Turn the Brushes vertically so they will fit into the

Brush Holders. Then, replace the Brush Caps. (See Figures B, C, and Assy.

Diagram.)

4.

Do not use solvents to wipe off the Polisher/Sander, as damage may result. If

necessary, wipe with a damp cloth. You may use a mild detergent.

5.

Do not introduce water, dirt, or dust into the electric motor through the motor

vents.

6.

Once clean, lubricate all moving parts with a light oil.

7.

When storing, keep the Polisher/Sander covered with a cloth cover.

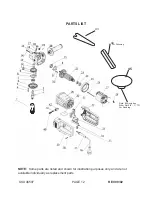

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR

SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALI-

FIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.