Page 7

4.4 Hardware Trigger

The microDAQ features a hardware trigger to enable the user to synchronise multiple microDAQ’s

and to calculate the timing of the measurements made. The hardware trigger takes the form of a

pulse train. Each time the microDAQ receives a positive edge, it will generate a set of

measurements for all the channels configured in the system.

4.4.1 Hardware Trigger Input.

The hardware trigger input is a 5V TTL square wave pulse train. Minimum frequency 2Hz and

maximum frequency 1.2KHz (32 channel scanner, real world application – theoretical maximum is

determined by the number of channels on the scanner. 64 channel units streaming data via TCP

comms will struggle to stream faster than around 600Hz)

4.4.2 Timing Information

The hardware trigger allows the user to calculate the time of each measurement. For example if the

hardware trigger were running at 100Hz then the user would receive 100 measurements per

channel per second. The first pulse would generate the first set of measurements and 10ms later

the second pulse would generate the second set and so on. When the hardware trigger is

activated, the microDAQ will wait for the first pulse. The time that this first pulse is generated can be

measured by the user and therefore the time of the first set of data and all subsequent sets can be

determined. For more details on hardware trigger timing a technical paper is available – Chell

document no. 900118 (this paper was developed for the CANdaq but applies to the microDAQ as

well).

4.4.3 Software Control

The hardware trigger mode is activated by the T command over the CAN or Ethernet interfaces.

The T command can be used to enable the hardware trigger that will cause the microDAQ to stop

free-running and wait for the first pulse. The disable command will return the microDAQ to free-

running. The command structure is as follows:

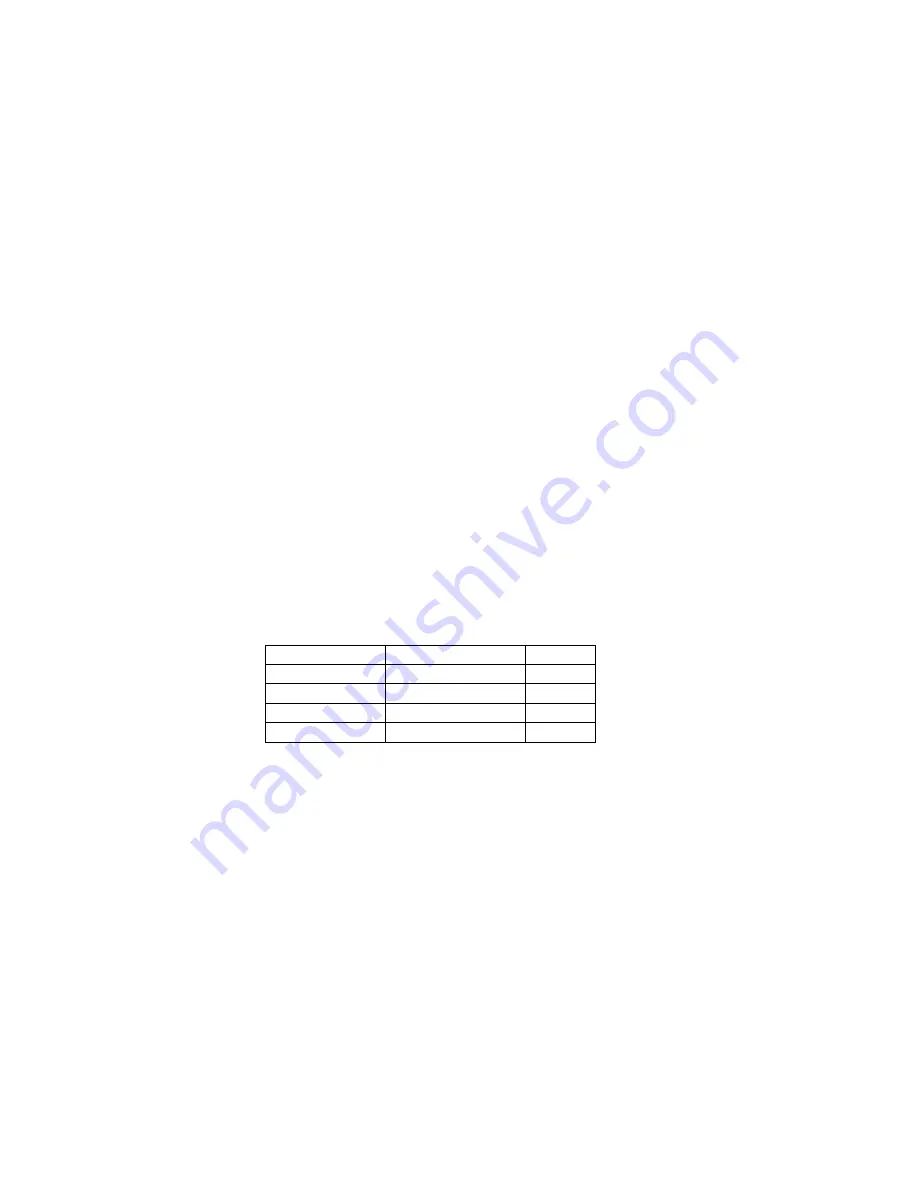

Command

Interface

On / Off

T01

CAN

Off

T11

CAN

On

T02

Ethernet

Off

T12

Ethernet

On

The hardware trigger can also be set to auto enable on power up which means that the microDAQ

will not go into free-running mode after initialisation and will instead wait for the first hardware

trigger pulse. In this instance the blue LED will not flash at a constant rate after initialisation and will

actually turn off. This feature can be enabled/disabled from the embedded webserver

configuration.