USER MANUAL

12

4.11

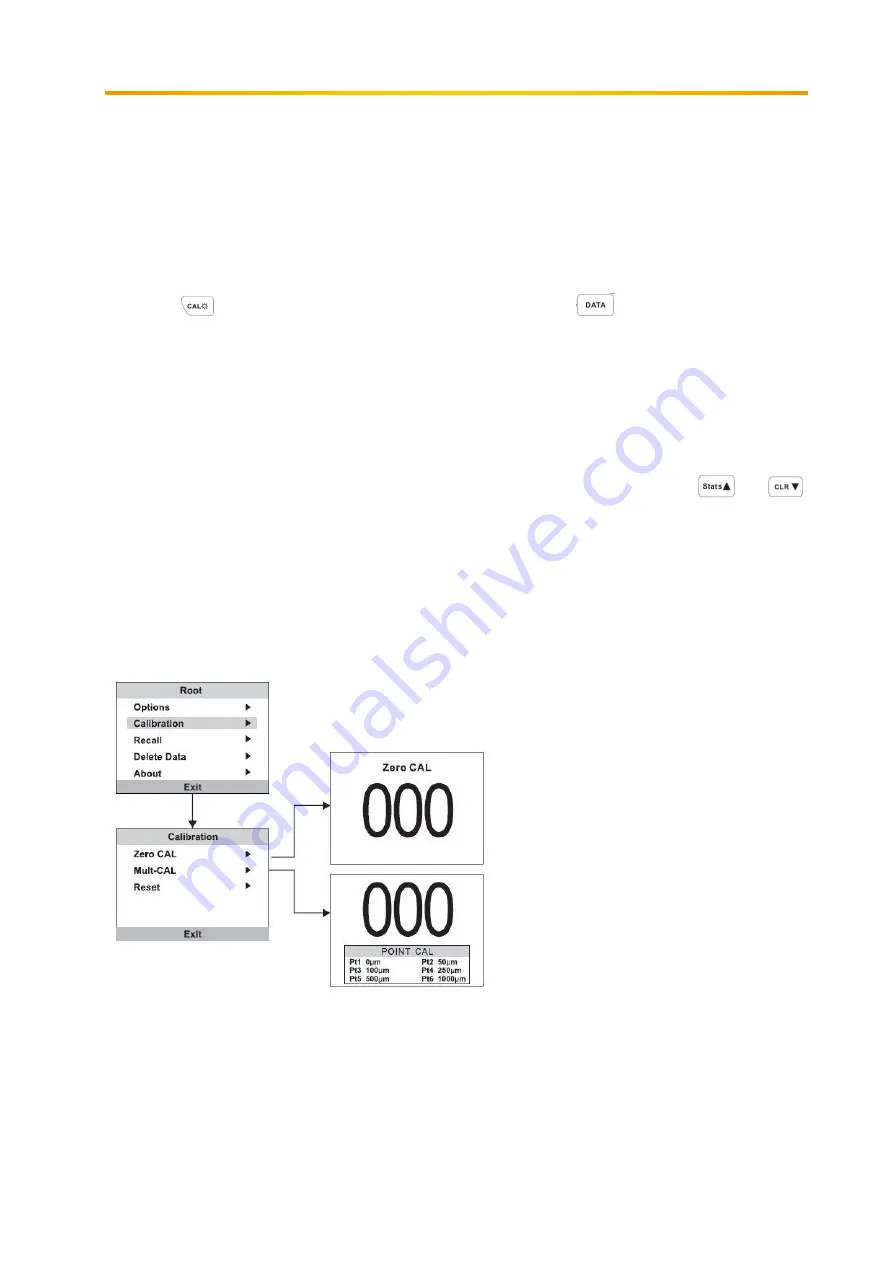

Calibration

The instrument has been factory calibrated and a built-in self-test function performed before the

measurement. Therefore, it usually only needs to be tested before the measurement if the measured

value is 0 when measuring an uncoated metal. If this is not the case, a zero point calibration should be

performed.

4.11.1

Zero-point calibration

Press the

and select "Zero Point Calibration" by briefly pressing

and "000" will flash on the

screen. Then measure an uncoated substrate. When "0" is displayed on the screen, the zero calibration

is successful. After this process, the instrument can usually be reused for accurate coating thickness

measurements. Nevertheless, due to abnormal base materials or extreme environmental conditions,

additive errors may occur. If this is the case, you can use the standard plastic films to perform a multipoint

calibration.

4.11.2 M

ultipoint calibration

Use the instrument to place standard plastic films on a calibration block if the value found is outside the

accuracy limits of this manual. Lift the probe ("Pt1 ~ μm" flashes in the screen to "), press

or

for fast scrolling) to set the value of the actual thickness. Repeat this with other plastic films. The use of

two of these standard plastic films is better for calibration than just one. For example, you can use a thin

and, alternatively, a thick foil. If the coatings to be measured are relatively close to the thickness of the

other, it is sufficient to use only a film of similar thickness for the calibration.