10

Operations

Product Manual - VaporMan 125

®

Manifold Vaporizer System

Connecting to the VaporMan 125

Unit

The VaporMan 125 unit is shipped with caps on the four

ports on the manifold If you are using two tanks, you will

need to remove all four caps If you are only using one tank,

only remove the left two caps or the two right caps The

transfer hoses that come with the unit can now be connected

to their proper ports. The diagrams in the Specifications

section of this manual tell which connections match between

the VaporMan 125 unit and the tanks The economizing

connections on the tanks should be connected to the two top

ports on the VaporMan 125 unit Each of these connections

are 5/8” flared fittings that will mate to the transfer hoses.

The gas use connections on the tanks should be routed to the

bottom two connections on the manifold Tighten each end of

each hose with a wrench Check for leaks before pressurizing

the system

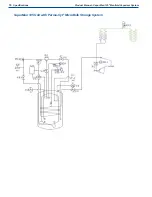

For a Carbo-Max

®

1000 Bulk CO

2

System the pressure

building circuits must be connected This allows the tanks

to equalize their head spaces This is an integral part in the

success of this set-up If the head spaces are not connected

the tanks may not distribute CO

2

to the VaporMan 125 unit

equally

The check valves are in place to prevent any back flow

into each tank The check valves also ensure that the tanks

equalize and feed the VaporMan 125 system equally

Delivering CO

2

to the VaporMan 125

System

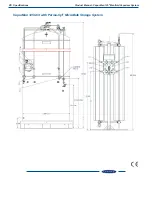

Once the connections are tightened and the entire unit has

been leak checked, the VaporMan 125 system can now be

used A regulator should be placed on the downstream side

of the VaporMan 125 unit to reach the desired delivery

pressure to your particular application The regulator can

be connected to the VaporMan 125 unit or placed further

downstream to take advantage of more vaporization The

final line regulator from one of the tanks may be used, or the

high flow regulator PN 11779806 can be ordered from Chart

Parts

The VaporMan 125 system has no isolation valves, therefore

the system is operated by opening all of the isolation valves

on each tank The economizing circuit, gas use circuit, and

the pressure building circuit (for Carbo-Max 1000 tank)

should all be opened on each tank The VaporMan 125 unit

will function as an extension of the tanks and will provide

vaporized CO

2

for your application

Caution! Once the isolation valves on the

tank have been opened pressure

should be allowed to escape from

the transfer hoses before they

are completely removed.