LiPo & LiFe, LiTo Battery Management System BMS24T V4.0

www.chargery.com

page 37 total 41

c)

The STOP button will NOT stop an Inverter while drawing power and will NOT stop charging if there is

current from the Charger. Loads & Charger must be OFF to allow the BMS to enter into Sleep Mode.

8.

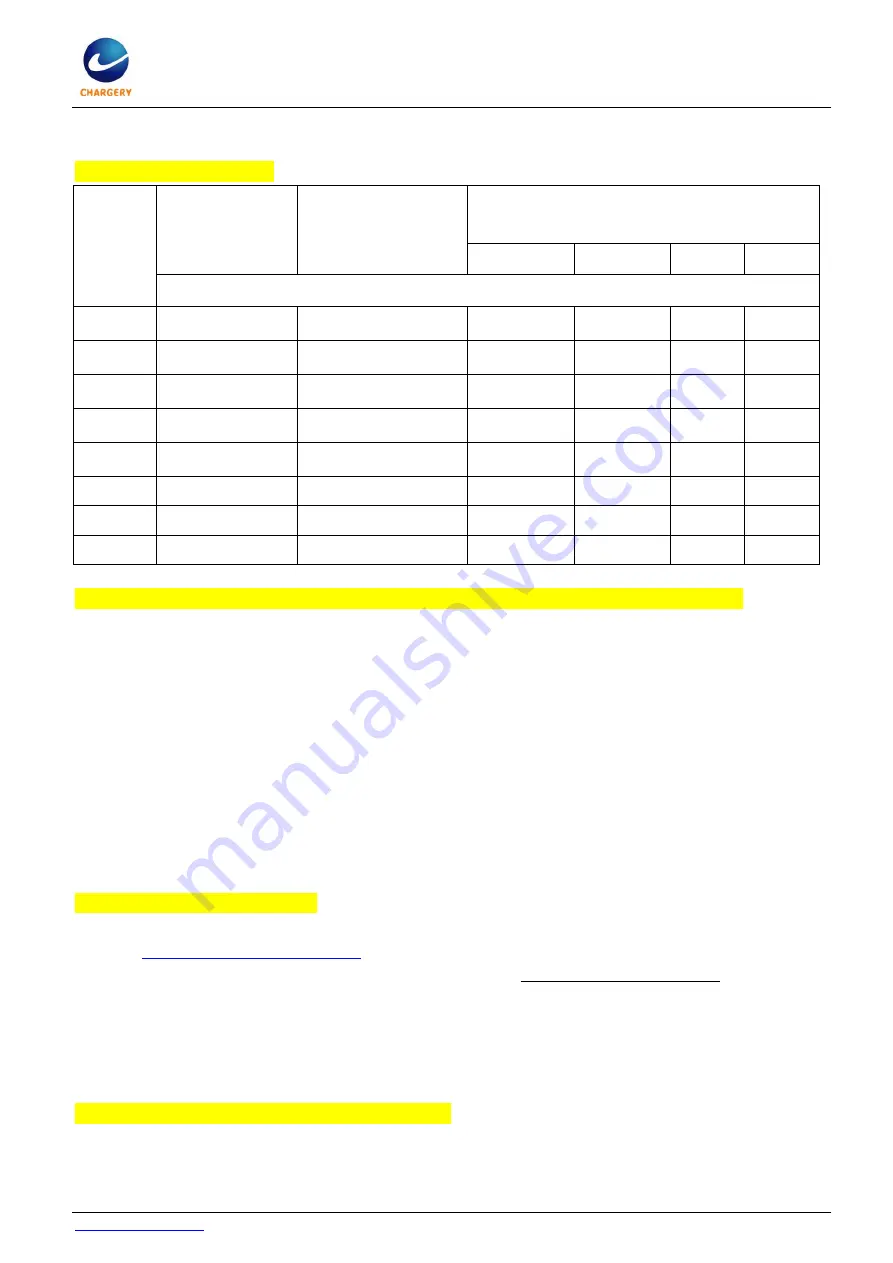

BMS power consumption

Battery

voltage

Normal mode

without Relay

but LCD is on

Sleep mode

without relay and

LCD is off

Normal mode with 12V mechanical relay

with different rated current and LCD is on

100A

200A

400A

600A

BMS drain current from battery (mA)

16V

120

40

500

850

1150

1425

24V

84.25

35

475

550

725

890

36V

65

50

325

365

485

587.5

48V

55

42.5

247.5

280

370

445

60V

48.75

29

207.5

230

302.5

365

67.2V

46

28.25

187.5

207.5

275

332.5

84V

40

27

150

170

222.5 266.25

96V

38.5

26.25

135

150

200

235

9.

BMS Relay controller output current at 12V when Chargery Mechanical Relay closed.

a)

12V 100A relay, coil current is 0.75A at 12V drive voltage.

b)

12V 200A relay, coil current is 0.96A at 12V drive voltage.

c)

12V 400A relay, coil current is 1.24A at 12V drive voltage.

d)

12V 600A relay, coil current is 1.3A at 12V drive voltage.

Because the relay coil current is far more than BMS working current, to avoid any cell being over

discharged, please operate as below,

a)

if the battery is not in use (exclude charging), please disconnect coil driven wire.

b)

If storage for over 1 month, please press STOP button place the BMS into Sleep Mode.

c)

If storage for over 3 months, please turn off the BMS directly. You may use the External / Internal

power switch if using internal power.

10.

Show timeout during updating,

a)

Download the correct firmware according to product model and save to your PC, from

http://chargery.com/update.asp

b)

Update tool software version must be v1.03 or greater. Always use the most current.

c)

Connect BMS main unit or LCD unit to the PC by using the provided USB cable.

d)

Turn on BMS main unit.

e)

Execute update tool software and lock the com port by click OPEN button.

f)

Click open file button and upload the correct firmware.

g)

Click update button finish update.

11.

Charging stops, the possible reasons are as below.

a)

Any cell voltage reaches “Over Charge Protection(P) Voltage“ setting.

b)

The highest cell voltage is over “Over Charge Release(R) Voltage” setting.

c)

Charging current is over “Over charge current” setting.