11

REV 92500-20140519

ENGLISH

92500

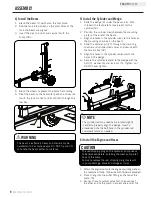

ASSEMBLy

The recommended oil type is 10W-30 automotive

oil.

NOTE

Weather will affect engine oil and engine

performance. Change the type of engine oil used

based on weather conditions to suit the engine

needs.

NOTE

The engine is equipped with a low oil shut-off and

will stop when the oil level in the crankcase falls

below the threshold level.

CAUTION

Add Engine Oil

1. Make sure the log splitter is on a flat, level surface.

2. Remove oil fill cap/dipstick to add oil.

3. Add upto 0.6 qt. (0.6 L) of oil (SAE 10W-30) - oil

should cover all but 2 threads of filler hole. Replace

oil fill cap/dipstick. DO NOT OVERFILL.

4. Check engine oil level daily and add as needed.

DO NOT attempt to crank or start the engine before

it has been properly filled with the recommended

type and amount of oil. Damage to the log splitter

as a result of failure to follow these instructions will

void your warranty.

CAUTION

Check oil often during the break-in period. Refer to

the Maintenance section for recommended service

intervals.

NOTE

Add Fuel

1. Use clean, fresh, regular unleaded fuel with a

minimum octane rating of 85 and an ethanol

content of less than 10% by volume.

2. DO NOT mix oil with fuel.

3. Clean the area around the fuel cap.

4. Remove the fuel cap.

5. Slowly add fuel to the tank. DO NOT OVERFILL.

Fuel can expand after filling. A minimum of ¼

in. (6.4 mm) of space left in the tank is required

for fuel expansion, more than ¼ in. (6.4 mm) is

recommended. Fuel can be forced out of the tank

as a result of expansion if it is overfilled, and can

affect the stable running condition of the product.

When filling the tank, it is recommended to leave

enough space for the fuel to expand.

Pouring fuel too fast through the fuel screen may

result in blow back of fuel at the operator while

filling.

WARNING

6. Screw on the fuel cap and wipe away any spilled

fuel.