19

REV 92500-20140519

ENGLISH

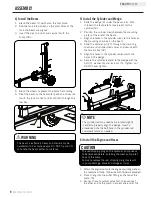

92500

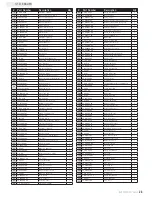

Engine Oil

Use 10W-30 automotive oil.

Oil capacity is 0.6 qt. (0.6 L).

DO NOT OVERFILL.

Please reference the following chart for recommended

oil types for use in the log splitter.

Fuel

Fuel capacity is 0.9 gallons (3.4 L). Use regular

unleaded gasoline with a minimum octane rating of 85

and an ethanol content of less than 10% by volume.

Log Splitter Specifications

– Ram Force

25 Ton

– Cycle Time

12 seconds

– Hydraulic Tank Capacity

4 gal (15.1 L)

– Max Log Length

23.8 in. (60.3 cm)

– Max Log Weight

100 lb. (45 kg)

– Coupler Ball Size

2 in. (5.1 cm)

– Tire Size

16 in. (40.6 cm)

– Max towing speed

45 MPH (72 KPH)

– Engine

224 cc, OHV, 4 stroke

– Cylinder size

4 in. x 22.6 in. (10.2 cm x 57.5 cm)

– Cylinder rod size

1.6 in. (4 cm)

– Gear Pump

2-stage

– Max pressure

3900 psi

– Max flow capacity

11 GPM

– Control Valve

Detent (auto-return)

–

Overall Dimensions

– Gross Weight

480.6 lb. (218 kg)

– Net Weight

436.5 lb. (198 kg)

– Height

44.7 in. (113.6 cm)

– Width

42.9 in. (109 cm)

– Length

89.3 in. (226.8 cm)

SPECIFICATIONS

Engine Specifications

– Model

YF172F-000

– Displacement

224 cc

– Type

4-Stroke OHV

– Start Type

Recoil

Maintenance Valve Clearance

– Intake: 0.13 – 0.17 mm (0.005 – 0.007 in.)

– Exhaust: 0.18 – 0.22 mm (0.007 – 0.009 in.)

Note: Tech bulletin regarding the valve adjustment

procedure is on www.championpowerequipment.com.

Spark Plugs

OEM spark plug: NHSP F6RTC

Replacement spark plug: NGK BPR6ES or equivalent

Make certain the spark plug gap is 0.7 - 0.8 mm or

(0.028 - 0.031 in.).

An Important Message About Temperature

Your Champion Power Equipment product is designed

and rated for continuous operation at ambient

temperatures up to 40°C (104°F). When your product is

needed your product may be operated at temperatures

ranging from -15°C (5°F) to 50°C (122°F) for short

periods. If the product is exposed to temperatures

outside this range during storage, it should be brought

back within this range before operation. In any event,

the product must always be operated outdoors, in a

well-ventilated area and away from doors, windows and

other vents.

Hydraulic Oil System

Oil capacity is 5 gallons (18.9 L).

For year round use in warmer climates

(always ABOVE 32 ˚F/0 ˚C):

– SAE 10W

– ISO 32

– SAE 32

– ISO 46

– ASLE H-150

– Universal Hydraulic/Transmission Fluid

For year round use in colder climates

(sometimes BELOW 32 ˚F/0 ˚C):

– Automatic Transmission Fluid

When temperature is below 32º F (0ºC) Automatic

Transmission Fluid (Dexron-III or similar).

NOTE