3

Important safety instructions

To prevent serious injuries resulting from loose parts

getting caught in the machinery, any cables or chains

connected to the door must be removed before you

install the door operator.

The three-button unit, the main disconnecting switch

and all other control equipment must be installed

within view of the door and out of reach of children.

Children should never be allowed to operate buttons

or remote control units. Misuse of the door opener

can lead to serious injuries.

When installing and connecting the equipment, the

locally applicable building and electrical regulations

must be observed. Electricity cables may only be

connected to a properly earthed network.

Do not install this equipment in damp or wet rooms.

Only one person at a time should ever carry out

works to the door opener.

Live and moving parts of electrical machines can

cause serious or fatal injuries. Assembly, connection

and initial operation as well as servicing and repair

works may only be carried out by qualified specialist

personnel.

When working on the door opener, all local safety

guidelines must be observed. This device must be

installed in accordance with EN12453.

The operator may only be connected and operated in

accordance with the door standard EN: 13241-1 or

with the domestic standard EN 60335-1.

The door opener may only be operated if the person

operating the equipment can see the entire door

area, the door area is free of obstructions, and the

door opener is properly adjusted. No one may walk

through the doorway when the door is in motion.

Children should never be allowed to play near the

door.

Before carrying out repair works or removing covers

from the door opener, install switch locks or discon-

nect the system from the power supply to ensure

that the operator cannot be set in motion unintenti-

onally.

All catches, fasteners and locks must be disabled

to prevent damage being caused to the door or the

door operator. Fix all catches, fasteners and locks in

the „open“ position. If a fastener needs to remain

operational, a release switch must be installed.

The technical data of the geared motor can be found on the identification plate or in

the accompanying documentation.

The following must be observed

:

- these instructions

- all further engineering documents relating to the door operator

- commissioning instructions and circuit diagrams

- the current national regulations (health and safety)

Warranty, storage

Compliance with the advice and instructions in this leaflet is the basis for trouble-free operation and for the acceptance of any warran

-

ty claims. Please check the contents of the package immediately on delivery for any transport damage. Report any damage immediately

to the transport company and also to the supplier. If you do not intend to install the geared motor immediately, store it in a dry, dust-

free, low-vibration room at a temperature between –10°C and +60°C.

Condition on delivery

Every geared motor is manufactured in accordance with the technical documentation applicable at Chamberlain and is subjected to

a test run. The technical data and design are subject to alterations, in the interest of technical progress. The equipment is shipped in

appropriate packaging.

Summary of Contents for DKK Series

Page 1: ...BEDIENUNGSANLEITUNG Industrietorantriebe DKK WKK DKN WKN DKS WKS ...

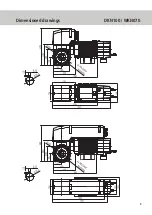

Page 8: ...8 Masszeichnungen DKK100 WKK070 ...

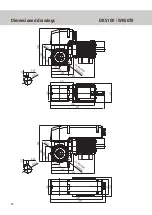

Page 9: ...9 Masszeichnungen DKN100 WKN070 ...

Page 10: ...10 Masszeichnungen DKS100 WKS070 ...

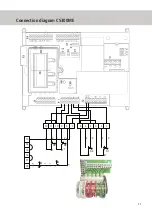

Page 11: ...11 Anschlussplan CS300ME ...

Page 12: ...OPERATING INSTRUCTIONS Industrial door operators DKK WKK DKN WKN DKS WKS ...

Page 19: ...8 Dimensioned drawings DKK100 WKK070 ...

Page 20: ...9 Dimensioned drawings DKN100 WKN070 ...

Page 21: ...10 Dimensioned drawings DKS100 WKS070 ...

Page 22: ...11 Connection diagram CS300ME ...

Page 23: ...INSTRUCTIONS DE SERVICE Commandes de portes industrielles DKK WKK DKN WKN DKS WKS ...

Page 30: ...8 Croquis coté DKK100 WKK070 ...

Page 31: ...9 Croquis coté DKN100 WKN070 ...

Page 32: ...10 Croquis coté DKS100 DKS070 ...