8

EXTREME ELECTRIC BUTTERFLY VALVE

6. INSTALLATION AND COMMISSIONING

Before starting the installation process, check that all the parts needed for the valve assembly are there, and that the materials,

connection type and nominal pressure are suitable for the installation.

For solvent or welded connections, ensure also that the parts to be connected are of the same material and that the correct solvent or

welding tools are used.

To install the valve, follow best installation practice recommendations provided on the Cepex website, paying specific attention to

thermal expansion and pipe alignment.

When filling the pipes with liquid, check that all the air has been purged from the system and that the initial pressure does not exceed

the nominal pressure of the valve, or of the system element with the lowest nominal pressure rating.

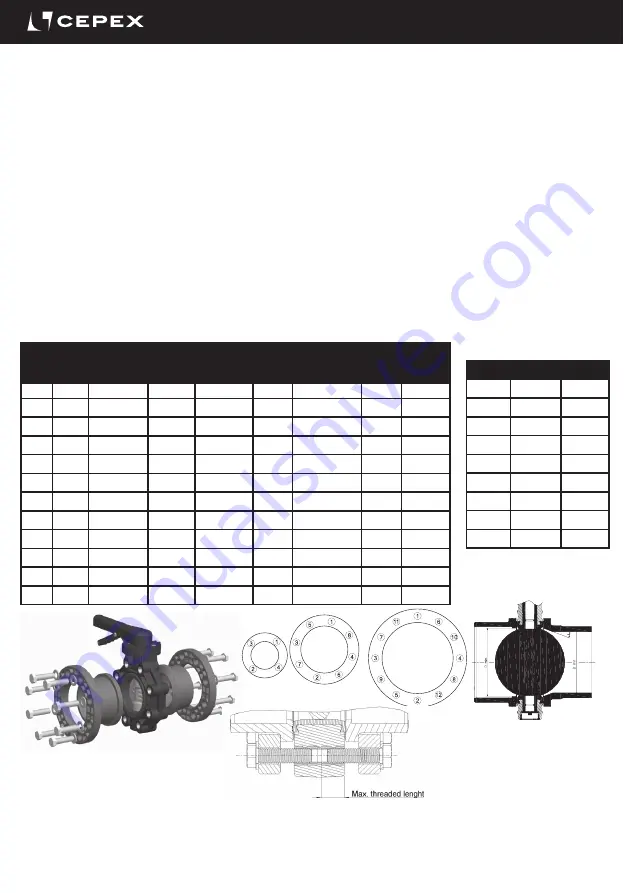

Valve assembly using standard ISO-DIN, ANSI, JIS and BS/E flanges. Flat gaskets are not needed in the socket couplings, as they are

incorporated in the valve itself. Observe the tightening sequence of the screws on the flanges (Fig. 6) and the maximum tightening

torque. All screws must be used in the flange in order to ensure proper operation of the valve.

The PP/PE sockets for butt welding must be chamfered as indicated in the diagram (Fig. 7) and table (T5.2), to ensure correct opening

and closing of the disc.

Install the valve once the sockets are solvent-bonded and dry, to avoid problems with the adhesive (entry of the latter into the valve).

Flanges must be well centred on the valve (pay special attention to measurements DN100-DN125 and DN200). Misalignment on

assembly could cause problems with the valve operation.

The threads of the screws and the inserts must be cleaned and lubricated in order to avoid seizing between the screw and the

insert.

The conditions of the installations and abience could need modifications in the installation standards.

An unnecessary over-torque will damage the flange.

D

DN

PN10

Screws (A2)

DIN (PN10)

inch

ANSI-150

Screws (A2)

ANSI-150

Insert

length

(mm)

Max. Threaded

lenght in both

sides L (mm)

Screws

Torque

(N·m)

Screws

Torque

(inch·lbs)

50

40

4xM16x2

1 1/2”

4xUNC 5/8

33

All

25

221

63

50

4xM16x2

2”

4xUNC 5/8

45

20

25

221

75

65

4xM16x2

2 1/2“

4xUNC 5/8

45

20

25

221

90

80

8xM16x2

3”

8xUNC 5/8

48

25

25

221

110

100

8xM16x2

4”

8xUNC 5/8

54

25

30

265

125

125

8xM16x2

64

25

35

310

140

125

8xM16x2

5”

8xUNC 3/4

64

25

35

310

160

150

8xM20x2,5

6”

8xUNC 3/4

70

25

40

354

200

200

8xM20x2,5

71

30

50

442

225

200

8xM20x2,5

8”

8xUNC 3/4

71

30

50

442

280

250

12xM20x2,5

10”

12xUNC 7/8

114

30

80

708

315

300

12xM20x2,5

12”

12xUNC 7/8

114

30

80

708

Screws and screw tightening torque

DN

D min.

x

40

31

30º

65

50.5

30º

80

70

30º

100

91.5

30º

125

113

30º

150

141

30º

200

191.5

20º

250

226

20º

300

296.5

20º

Fig. 4

Fig. 5

Fig. 6

Pipe and chamfer

measurements

PP/PE sockets

T 6.2

T 6.1

Recommended

installation