11

10.

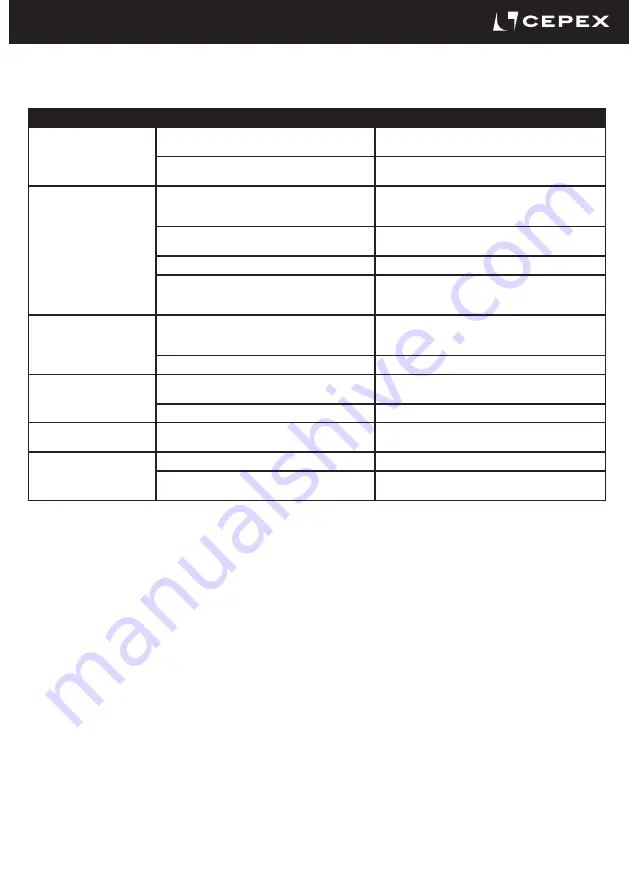

TROUBLESHOOTING

T 9.1

FAULT

POSSIBLE CAUSE

FAULT CLEARANCE

The disc does not fully open

or close.

The sockets were not correctly bevelled.

Disassemble the valve and bevel the sockets as indicated

in table T6.2.

Foreign materials in the compartment (adhesive, etc.).

Disassemble the valve and check for obstructions in the

disc and gasket contact area.

Excessive opening or closing

torque.

The valve has been inactive for a long time.

Operate with an auxiliary release key (not the plastic

handle).

Disassemble the valve and lubricate the sealing gasket.

High temperatures or chemicals can cause damage to

the gasket.

Check the chemical compatibility of the liquid with the

disc and the working temperature. Replace the gasket.

Excessive flange torque.

Tighten flanges as indicated in table T5.1.

Misalignment between sockets and valve.

Disassemble the valve and reassemble with concentric

alignment (observe the correct tightening sequence and

torque).

The valve is not completely

watertight in the sockets.

Misalignment between sockets and valve.

Disassemble the valve and reassemble with concentric

alignment (observe the correct tightening sequence and

torque).

Flange screws not tight enough.

Tighten flanges as indicated in table T6.1.

The valve is not completely

watertight at the sealing

gasket.

Inadequate chemical resistance.

Check compliance with the specifications in this

document.

Temperature out of range.

Replace the gasket.

The valve does not open or

close.

Lack of current.

Check power supply to the actuator.

The valve does not close

completely.

The actuator stroke is not well adjusted to the valve.

Check adjustment limits according to the actuator manual.

The torque of the valve has increased above the

calculated value.

Check the valve: obstructions in the disc or malfunction

of the valve.

EXTREME ELECTRIC BUTTERFLY VALVE