Page 54

Installation and Operation Manual - FW2900

ENGLISH

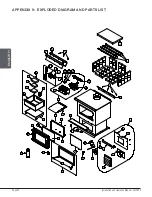

#

Item

Description

Qty

34

44028

CERAMIC THERMODISC F110-20F

1

35

PL05530-02 THERMODISC BOX (COVER)

1

36

60013

POWER CORD 96" X 18-3 type SJT (50 pcs per carton)

2

37

AC02050

BLOWER ASSEMBLY WITH VARIABLE SPEED CONTROL (UP TO 100 CFM)

1

38

PL09909-02 BLOWER HOUSING

1

39

44073

CROSSFLOW BLOWER 115V-60Hz-39W 100 CFM

1

40

44080

RHEOSTAT WITHOUT NUT (MODEL KBMS-13BV)

1

41

44087

RHEOSTAT NUT

1

42

44085

RHEOSTAT KNOB

1

43

PL74047

PEDESTAL FRONT COVER

1

44

AC07869

3/8" BLACK COIL HANDLE

1

45

AC05959

METALLIC BLACK STOVE PAINT - 342 g (12oz) AEROSOL

1

46

AC01315

RIGID FIRESCREEN

1

47

30898

ROUND WOODEN BLACK HANDLE

2

48

AC02081

5"Ø FRESH AIR INTAKE KIT

1

49

PL74054

BACK OF THE BASE

1

50

PL74055

FACE PLATE

1

51

SE65598

AIR INTAKE ADAPTER

1