17

System Installation

14.8.

Additional System Settings can be adjusted at this time.

14.9.

Select the Back icon to return to the Home Screen.

15.

Calibrate the system balance using a 10 g weight.

15.1.

Select the System Menu icon in the bottom right corner of the screen to open the Menu screen.

15.2.

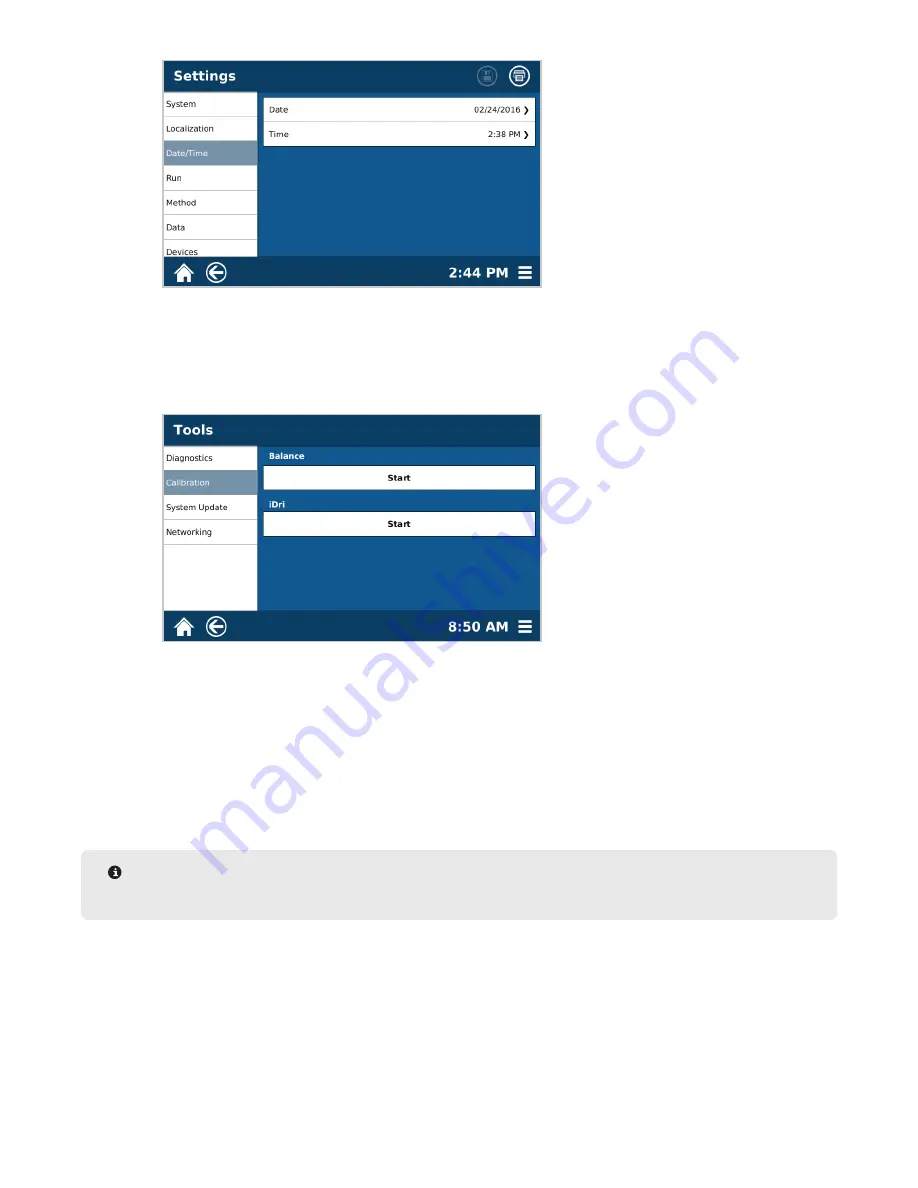

Select Tools, followed by Calibration

15.3.

Using a calibrated traceable 10 g weight, press Start and follow the instructions on the screen to per-

form the balance calibration. Once the calibration is completed, press the Home icon to return to the

main menu.

16.

Select the System Menu icon in the bottom right corner of the screen to open the Menu screen.

17.

Select Video. Watch the videos titled “Intro” and “Run Sample.”

18.

After reviewing the process for performing a sample method, use the MONITOR One Touch method to test the

monitor solution provided with the instrument. Follow the instructions on the screen to ensure the instrument

is performing within proper specifications.

NOTE

See the ORACLE or Trac Fat Analyzer manual if connecting at this time.

19.

Register the system by accessing www.cem.com and selecting “account” from the top right corner.

• For new logins, select “Signup” from the menu and follow the instructions. Name, contact information, and

unit serial numbers are required for a new login.

• For existing logins, login and update your profile with your new serial number to gain access to owner

content.