Every care has been taken to ensure the accuracy of the information contained in this publication, but due to continuous development and improvement the right is reserved to supply products

which may differ slightly from those illustrated and described in this publication.

19

www

.ceg.co

www

.ceg.co

www

.ceg.co

www

.ceg.co

www

.ceg.co

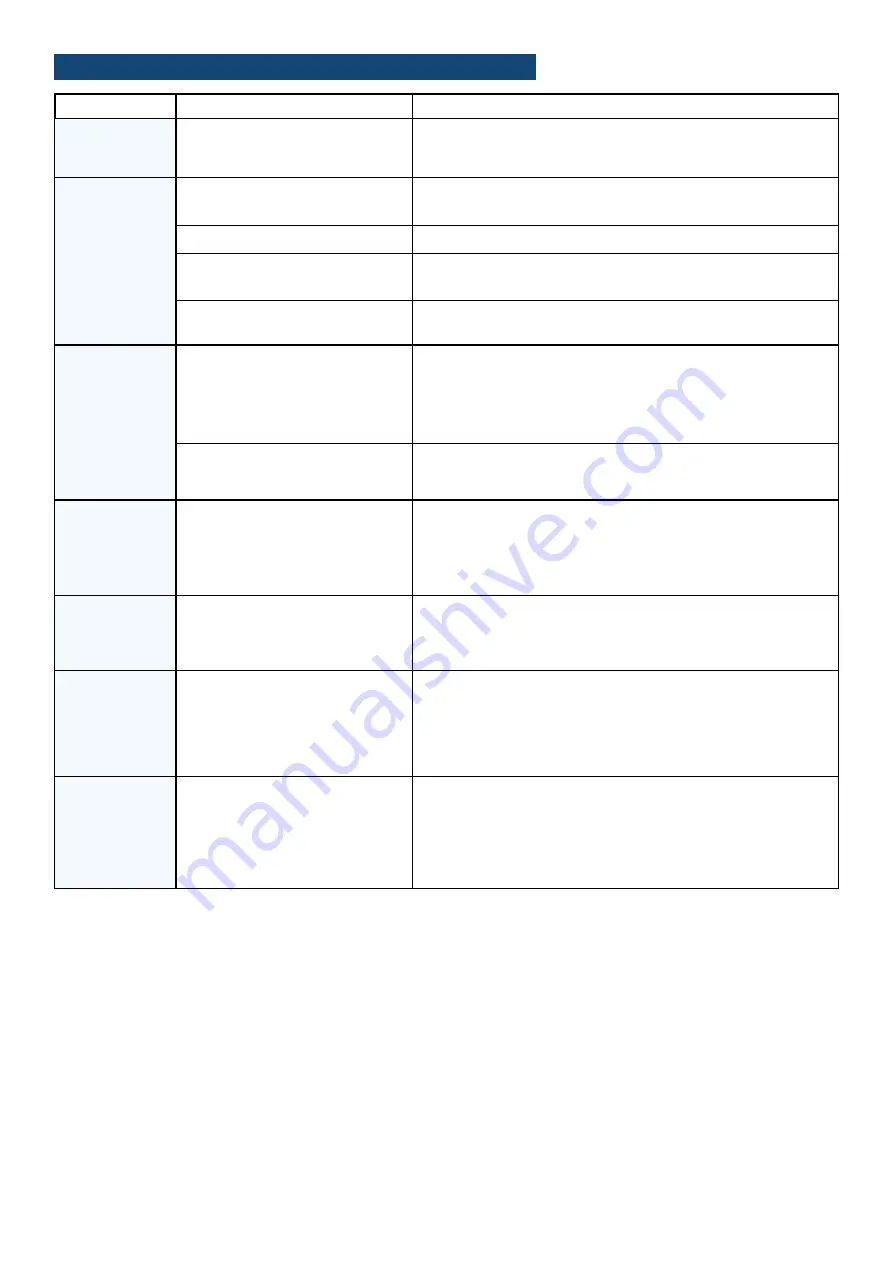

Faults

Causes

Solutions

Pump does not

run

Interruption of the power supply,

short circuit or an insulation fault in

the motor coil

Check power supply

Call an expert to check the pump unit

Pump runs,

but little or no

delivery

Pump or pipes are blocked due to

foreign matters

Lack of supply water

Primed incorrectly

Air in suction pipes

Check all filters/check valve for foreign matters

Ensure all taps are turned on

Repeat priming procedure (refer to page 8 for flooded suction or

page 9 for lift suction) to remove any air from the system

Check the tightness of the whole pipe up until the pump and

tighten it

Motor overheats

Low voltage

Ambient temperature above +40 °C

or insufficient ventilation

Ensure power supply is not running on an extended cable

exceeding 10m. Check voltage on terminals of the motor. It should

be within ± 10 % of 230V (this should be carried out only by

qualified personnel)

Relocate pump to a cooler, better ventilated environment

The flow is too

little

Length of pipe is excessive and

diameter is too small

Excessive head

Decrease pipe length and increase pipe size (diameter)

Decrease head on pump

Pump vibrates

Fuse blows or

circuit breaker

trips when pump

starts

Controller failure

light

Incorrectly mounted/fixed

Pump jammed.

Motor stator may be defective,

circuit leakage or insulation failure.

Fuse size or circuit breaker may be

too small

Loss of prime or no water in tank

Electronic controller faulty, maybe

damaged by power surge or spike

Ensure pump is fastened to a solid surface by two mounting

screws

Get pump serviced

Check pump is primed and water supply is sufficient

Replace controller

FAULTS, CAUSES AND SOLUTIONS