17

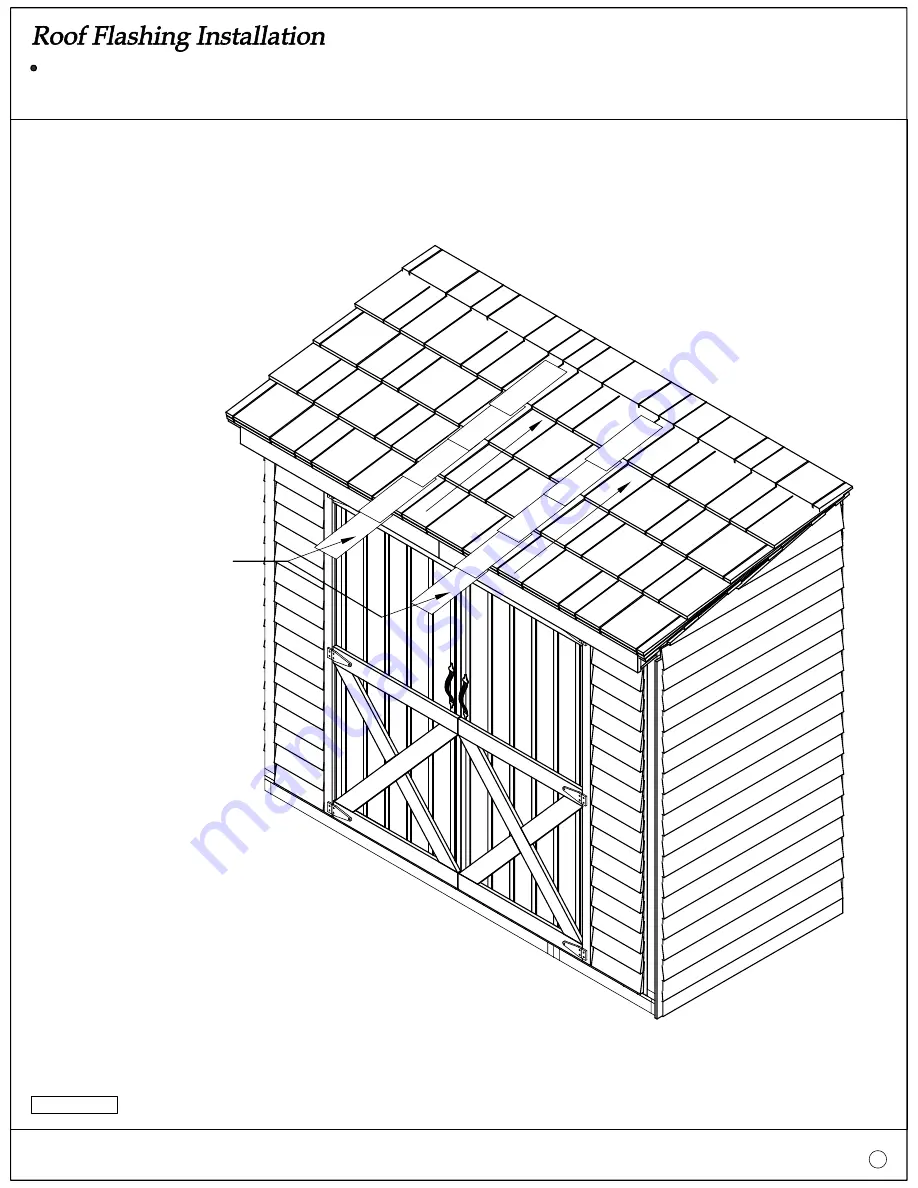

FIGURE S16

Slide Metal Flashing under each

row of cedar shingles up the full

length of the Roof Joint Seam.

When complete, take the Metal Flashing Shingles and slide them one by one between the rows of Cedar Shingles along the

Roof Panels Joints (FIGURE S15)

B84DD

H-

MF

LA

SS

H-

MF

LA

SS